ISO 8516 pdf download

ISO 8516 pdf download Textile glass — Textured yarns — Basis for a specification

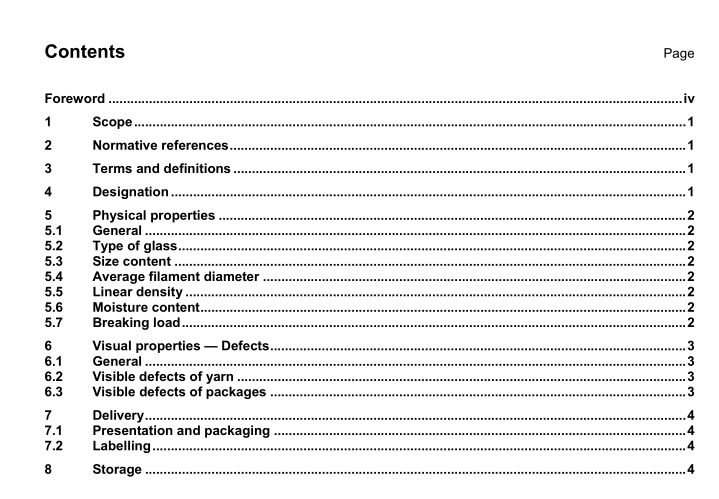

1 Scope

This International Standard provides a basis for a specification applicable to textured yarns made from single or folded yarns of textile glass.

Textured glass yarns can be produced by several types of process. They can be made starting either from a single strand or from two or more strands in which one or more have been “opened” to give the “bulky” aspect of textured yarn.

Textured glass yarn is used in various applications, for example insulation, filtration, the manufacture of decorative textiles, the reinforcement of plastics and the manufacture of packing materials.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 472, Plastics — Vocabulary

ISO 1887, Textile glass — Determination of combustible-matter content

ISO 1888, Textile glass — Staple fibres or filaments — Determination of average diameter

ISO 1889, Reinforcement yarns — Determination of linear density

ISO 2078, Textile glass — Yarns — Designation

ISO 3341, Textile glass — Yarns — Determination of breaking force and breaking elongation

ISO 3344, Reinforcement products — Determination of moisture content

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 472 apply.

4 Designation

The designation of the yarn shall conform to ISO 2078.

5 Physical properties

5.1General

Unless otherwise agreed, textured glass yarns shall be defined by the characteristics specified in 5.2 to 5.7,and nominal values and tolerances shall be given for these characteristics in the suppliers technicalspecification.

The criteria for acceptance or rejection of a batch, based on the results of testing, shall also be given in thesupplier’s specification.

5.2Type of glass

Various types of glass are used in the production of textured yarns. A list of available glass types is given inIso 2078.

5.3size content

The texturizing process requires the use of yarn covered with size to give suitable lubrication duringtexturization. This size can be eliminated after weaving by a heat-cleaning treatment, if necessary. The sizecontent shall be determined in accordance with ISO 1887.

5.4Average filament diameter

The average filament diameter shall be determined in accordance with lSO 1888.

5.5Linear density

The linear density shall be determined in accordance with ISO 1889,taking care,when taking the testspecimens,that the yarn is tensioned to a level suitable for staple-fibre yarns in order to ensure that thespecimens will be of the required length.

5.6Moisture content

The moisture content shall be determined in accordance with ISO 3344.