ISO 4666-4 pdf download

ISO 4666-4 pdf download Rubber, vulcanized — Determination of temperature rise and resistance to fatigue in flexometer testing — Part 4: Constant-stress flexometer

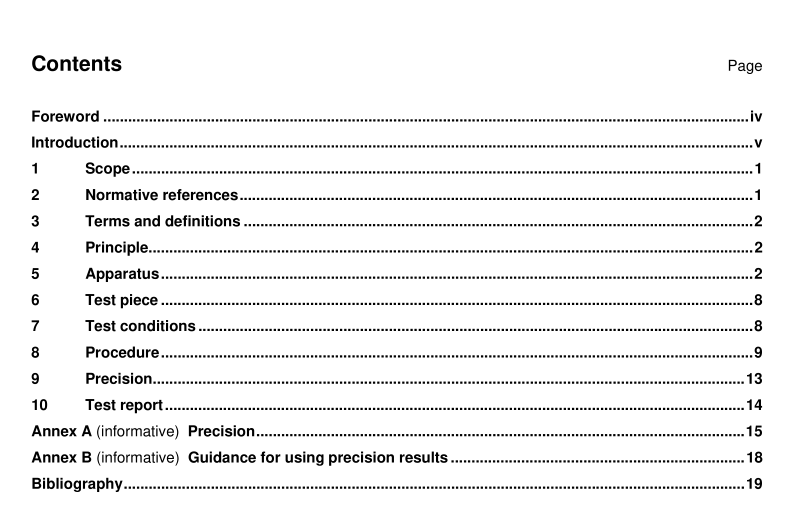

Scope

This part of ISO 4666 specifies a constant-stress flexometer test for the determination of the temperature riseand resistance to fatique of vulcanized rubbers.

Many rubber products, such as tyres and belts, are tested by subjecting them to an oscillating load with aconstant peak stress amplitude. In order to obtain good correlation between accelerated tests and in-serviceexposure of these products, this part of ISO 4666 gives instructions for carrying out measurements undersuch conditions.

This method is not recommended for rubber having a hardness greater than 85 IRHD

2 Normative references

The following referenced documents are indispensable for the application of this document. For datedreferences, only the edition cited applies. For undated references, the latest edition of the referenceddocument (including any amendments) applies

SO 48, Rubber, vulcanized or thermoplastic — Determination of hardness (hardness between 10 IRHD and100 IRHD)

ISO 4664-1, Rubber, vulcanized or thermoplastic 一- Determination of dynamic properties — Part 1: Generalquidance

ISO 4666-1, Rubber, vulcanized — Determination of temperature rise and resistance to fatigue in flexometertesting – Part 1: Basic principles

ISO 4666-3, Rubber, vulcanized — Determination of temperature rise and resistance to fatique in flexometertesting – Part 3: Compression flexometer

ISO 23529, Rubber — General procedures for preparing and conditioning test pieces for physical testmethods

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 4664-1 and ISO 4666-1 apply.

4 Principle

A cylindrical test piece is subjected to dynamic loading with constant peak stress cycles in compressionsuperimposed on a static prestress.

The temperature rise of the test piece is measured, and the fatique life of the test piece is given by the numberof cycles, or the test time, until breakdown occurs. The change in height (creep) and dynamic properties arealso measured as a function of time, and the compression set is measured at the end of the test.

Apparatus5

The apparatus is shown schematically in Figure 1, and an example is shown in Figure 2.

5.1Anvils

A pair of anvils (upper and lower) support the test piece. The lower anvil is connected to an oscillator to applystatic and dynamic compression deformation to the test piece, and the upper anvil transmits the static ancdynamic compression loads, via a shaft, to a load detector. The parts of the upper and lower anvils whichcome in contact with the test piece shall be made of a heat-insulating materia of thermal conductivity0.28 W/(mk) maximum. A hole shall be provided in the centre of the upper anvil for insertion of a needle-typethermometer for measuring the temperature inside the test piece. An example of upper and lower anvilconstruction is shown in Figure 3.

5.2Oscillator

The oscillator used to apply static and dynamic compression loads to the test piece shall have a capacity of atleast 2 kN and be capable of applying an oscillating force of 0,75 kN peak amplitude at 50 Hz.

A hydraulic servo-control system is preferably used to control the oscillator

The maximum stroke is preferably 20 mm to 25 mm.

5.3Displacement detector

The displacement detector shall be capable of measuring the motion of the lower anvil (the deformation of thetest piece in compression) to within 0.01 mm, and shall have a response time suitable for the maximumfrequency used.