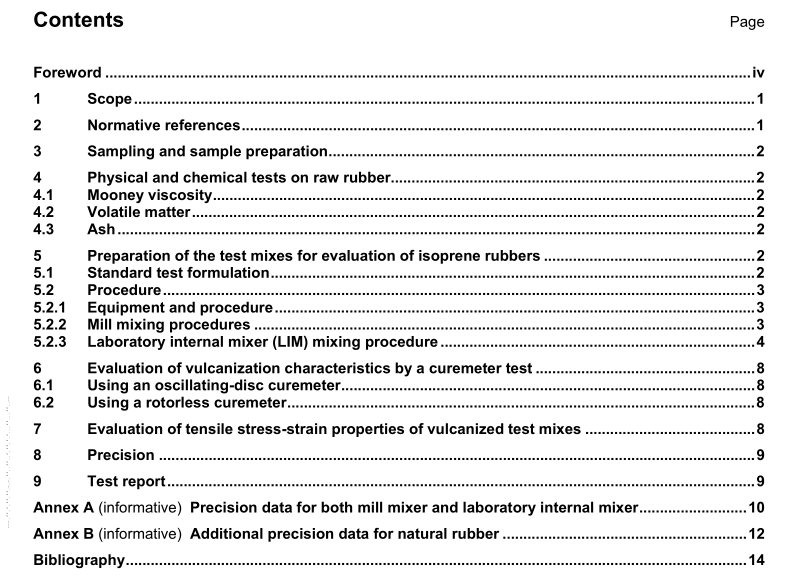

ISO 2303 pdf download

ISO 2303 pdf download Isoprene rubber (IR) — Non-oil-extended, solution-polymerized types — Evaluation procedures

1 Scope

This International Standard specifies, for general-purpose non-oil-extended, solution-polymerized polyisoprene rubbers (IR):

physical and chemical tests on raw rubbers;

standard materials, a standard test formulation, equipment and processing methods for evaluating the vulcanization characteristics.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 37, Rubber, vulcanized or thermoplastic — Determination of tensile stress-strain properties

ISO 247:2006, Rubber — Determination of ash

ISO 248-1, Rubber, raw — Determination of volatile-matter content — Part 1: Hot-mill method and oven method

ISO 289-1, Rubber, unvulcanized — Determinations using a shearing-disc viscometer — Part 1:Determination of Mooney viscosity

ISO 1795, Rubber, raw natural and raw synthetic — Sampling and further preparative procedures

ISO 2393, Rubber test mixes — Preparation, mixing and vulcanization — Equipment and procedures

ISO 3417, Rubber — Measurement of vulcanization characteristics with the oscillating disc curemeter

ISO 6502, Rubber — Guide to the use of curemeters

ISO 23529, Rubber — General procedures for preparing and conditioning test pieces for physical test methods

3 Sampling and sample preparation

3.1 A laboratory sample of approximately 1,5 kg shall be taken by the method described in ISO 1795.

3.2 Preparation of the test portion shall be in accordance with ISO 1795.

4 Physical and chemical tests on raw rubber

4.1 Mooney viscosity

The Mooney viscosity shall be determined in accordance with ISO 289-1 on a test portion prepared as described in ISO 1795 (without massing).

The result shall be recorded as ML(1 4) at 100 °C.

4.2 Volatile matter

The volatile-matter content shall be determined in accordance with ISO 248-1.

4.3 Ash

The ash content shall be determined in accordance with ISO 247.

5 Preparation of the test mixes for evaluation of isoprene rubbers

5.1 Standard test formulation

The standard test formulation is given in Table 1.

The materials shall be national or international standard reference materials. If no standard reference material is available, the materials to be used shall be agreed by the interested parties.

5.2Procedure

5.2.1Equipment and procedure

Equipment and procedure for the preparation, mixing and vulcanization shall be in accordance with ISO 2393.5.2.2Mill mixing procedures

5.2.2.1General

Two mill mixing procedures are specified: methods A and B. The mixing time is shorter in method B than inmethod A.

The two methods do not necessarily give identical results. In laboratory cross-checks or in a series ofevaluations, the same procedure shall be used in all cases.

In both methods, the standard laboratory mill batch mass, in grams, shall be based on four times the formulamass. The surface temperature of the rolls shall be maintained at 70 °C±5°C throughout the mixing.

A good rolling bank at the nip of the rolls shall be maintained during mixing. f this is not obtained with the nipsettings specified in 5.2.2.2 and 5.2.2.3, small adjustments to the mill openings might be necessary.