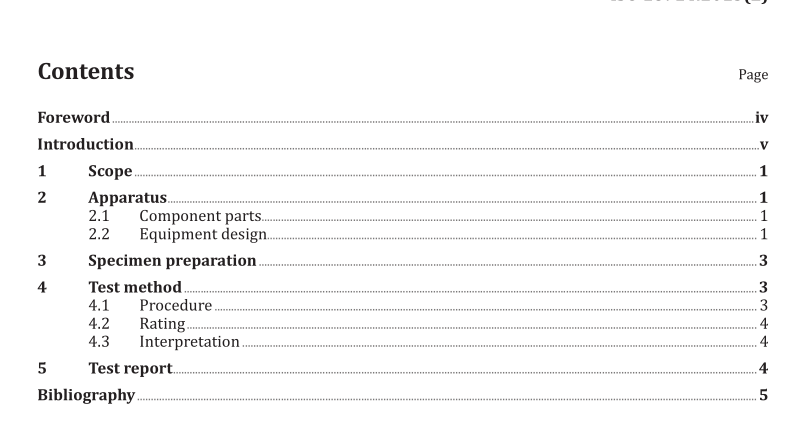

ISO 18914 pdf download

ISO 18914 pdf download Imaging materials — Photographic film and papers — Method for determining the resistance of photographic emulsions to wet abrasion

1 Scope

This International Standard specifies a laboratory test method for determining the resistance ofphotographic emulsions or gelatin backings to abrasion damage during processing.

This method may be used to determine the effects of variations in processing solutions, gelatin layerproperties, processing solution temperatures and times, or a combination of these factors, on the wetscratch resistance of gelatin layers.

This method is applicable to the determination ofthe physical integrity of photographic emulsions whenwet, but it is not applicable to the evaluation of the scratch resistance of the support material.

2 Apparatus

2.1 Component parts

The apparatus shall consist of the following elements:

a specimen tray in which the specimen can be immersed in either distilled water or a processingsolution. The tray shall be free to move smoothly in a horizontal plane for a distance of at least30 mm without sideways displacement and may be either manually operated or power driven;

a spherical sapphire or diamond stylusl) mounted at the end of a pivoted arm, so that it can belowered onto the specimen and thereby scribe a line on it when the specimen tray travels alongunder the stylus. The stylus shall make perpendicular contact with the specimen in the traycontaining the solution. A 0,38 mm radius stylus should be used for emulsions on photographic filmbase and a 0,20 mm radius stylus for emulsions on photographic paper base. The stylus arm shallbe counterbalanced so that, when the stylus arm is lowered and the stylus rests on the emulsionsurface, there is no load on the stylus.

NOTE 1 lt is very important that the stylus is smooth and has a uniform radius. Although diamond styli havelow friction properties in the dry state, they are satisfactory in this wet application.Diamond styli will wear betterthan sapphire in high usage circumstances. Diamond styli that have been satisfactory are those compoundedfrom diamond particles.

NOTE 2The test apparatus for dry scratch resistance, described in lSO 18922, may be modified for this test.

2.2 Equipment design

2.2.1 General

The equipment may be constructed in either oftwo formats.

2.2.2 Constant load instrument

In the constant load instrument, weights are added directly to a pan and the apparatus shall be designed so that the centre of gravity of the weights will be positioned directly over the stylus. These weights should range from 1 g to 210 g. The arm may be pivoted on a threaded hinge with a knurled knob, or other provision for positioning the stylus laterally, so that many parallel scribe lines can be made on the same specimen. As an alternative, the specimen holder can be provided with lateral positioning and a simple pivot used on the stylus arm.

2.2.3 Continuous load instrument

Alternatively, the continuous load instrument (illustrated in Figure 1) can be used 2) . As the arm is lowered, the sliding weight is engaged by the carriage so that, when the sliding carriage with the tray is moved away from the fulcrum of the arm, the weight slides with it. This produces an increasing weight on the stylus point as the tray moves with the carriage. This weight increases from 0 g to 70 g, as the carriage moves its full travel of 180 mm. To increase the range of the apparatus, additional weights of 50 g, 100 g, and 150 g can be screwed onto the threaded rod directly over the stylus.