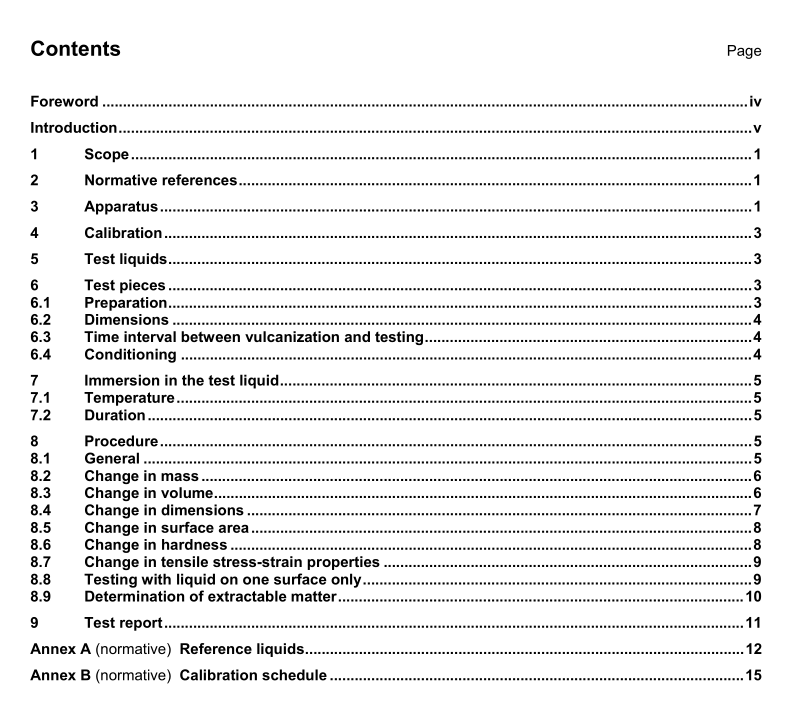

ISO 1817 pdf download

ISO 1817 pdf download Rubber, vulcanized or thermoplastic — Determination of the effect of liquids

1Scope

This International Standard describes methods of evaluating the resistance of vulcanized and thermoplasticrubbers to the action of liquids by measurement of properties of the rubbers before and after immersion in testliquids. The liquids concerned include current service liquids, such as petroleum derivatives, organic solventsand chemical reagents, as well as reference test liquids.

2Normative references

The following referenced documents are indispensable for the application of this document.For datedreferences,only the edition cited applies. For undated references,the latest edition of the referenceddocument (including any amendments)applies.

ISO 37, Rubber,vulcanized or thermoplastic —Determination of tensile stress-strain properties

ISO 48,Rubber,vulcanized or thermoplastic —Determination of hardness (hardness between 10 IRHD and100 lRHD)

IS0 175, Plastics —Methods of test for the determination of the effects of immersion in liquid chemicalsISO7619-1,Rubber,vulcanized or thermoplastic—Determination of indentation hardness— Part 1:Durometer method (Shore hardness)

ISO 18899:2004,Rubber – Guide to the calibration of test equipment

ISO 23529:2010,Rubber — General procedures for preparing and conditioning test pieces for physical testmethods

ASTMD5964,Standard Practice for Rubber lRM 901,IRM 902,and IRM 903 Replacement Oils for ASTMNo. 1,ASTM No. 2, and ASTM No.3 Oils

3Apparatus

3.1 Total immersion apparatus, designed to take account of the volatility of the test liquid and of theimmersion temperature in order to prevent and minimize evaporation of the test liquid and the ingrFor tests at temperatures considerably below the boiling point of the test liquid, a stoppered glass bottle or tube shall be used. For tests at temperatures near the boiling point of the test liquid, the bottle or tube shall be fitted with a reflux condenser or other suitable means of minimizing the evaporation of liquid.

The bottle or tube shall be so dimensioned that the test pieces remain completely immersed and all surfaces are completely exposed to the liquid without any restriction. The volume of liquid shall be at least 15 times the combined volume of the test pieces and the volume of air above the liquid shall be kept to a minimum.

The test pieces shall be mounted in jigs, preferably hanging on a rod or wire, and separated from any adjacent test piece, for instance by glass rings or other non-reactive spacers.

The materials of the apparatus shall be inert to the test liquid and to the rubber; for example, materials containing copper shall not be used.ess of air.