ISO 17718 pdf download

ISO 17718 pdf download wheat (Triticum aestivum L.)

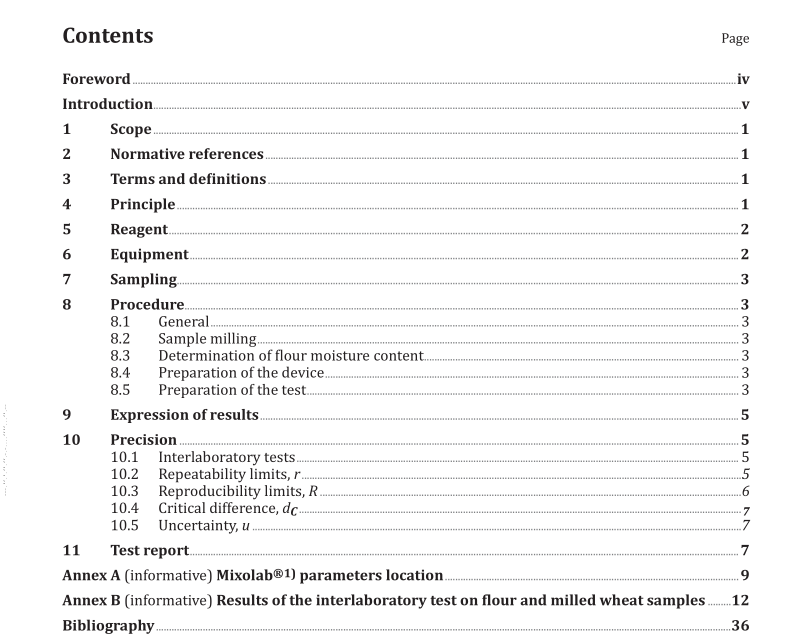

Scope

This International Standard specifies the determination of rheological behaviour as a function olmixing and temperature increase. lt is applicable to all wholemeal and flour samples from industrial orlaboratory milling of wheat (Triticum aestivum L..

NOTEWheat can be milled in the laboratory according to the methods described in ISO 2797115] or in BIPEAguidance document BY.102.D.9302[z]

2 Normative references

The following documents,in whole or in part, are normatively referenced in this document and areindispensable for its application. For dated references, only the edition cited applies. For undatedreferences, the latest edition of the referenced document (including any amendments) applies

ISO 712, Cereals and cereal products — Determination ofmoisture content — Reference method

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.3.1water absorption

volume of water required to obtain a dough with a maximum consistency of (1,10 + 0,05) Nm

Note 1 to entry: Water absorption is expressed in millilitres per 100 g of flour with a moisture content of 14 %mass fraction.

3.2

time T1time required for the dough to reach the target consistency C1 of(1,10 + 0,05) Nm

Note 1 to entry: Development time is expressed in minutes.

3.3

stability

calculated time during which the dough achieves a consistency higher than C1 – 11 % x C1

Principle4.

Dough behaviour is determined as it is subjected to a combined kneading and temperature treatmentduring a constant temperature phase, followed by a heating phase, then held at high temperatureand subsequently cooled. Water is added to flour to achieve a maximum dough consistency of (1,10 +005) Nm during the first constant temperature phase.

The dough is first kneaded between two mixing arms rotating in opposite directions at 80 r/min, ata starting temperature of 30 °C. The torque that the dough creates between the two mixing arms isrecorded. Kneading then continues while temperature is increased to 90 at a rate of 4 C/min. The temperature is then held at a controlled 90 °C for 15 min, The dough mixer is then cooled at a rate of4·C/min to a temperature of 50 ·C

Dough consistency, like temperature, is recorded throughout the test. The results provide informationon gluten strength, starch gelatinization and retrogradation, enzyme activity, and all the interactionstaking place between dough components throughout the process.

5 Reagent

Use only distilled or demineralized water or water of equivalent purity.

6 Equipment

Usual laboratory apparatus and, in particular, the following.

Chopin Mixolab@,1) including the following components6.1

Drive motor, capable of delivering a mixing arm rotation speed of 80 r/min.6.1.1

6.1.2Water tank, containing water (Clause 5) thermostatically maintained at 30 C

6.1.3Dough mixer, comprising a bowl, two hub-flanges, and two detachable mixing arms.

6.1.4Removable cover,for positioning the water injection nozzle.

6.1.5 Water injection nozzle, fitted with four delivery channels.

6.1.6 Software, for programming the test conditions and measuring and recording the test results

6.2 Laboratory scale, capable of weighing to +0,1 g

Laboratory mill, hammermill model,2)6.3

fitted with a 0,8 mm mesh sieve and able to provide a wholemeal flour of specified homogeneousparticle size.

Mill performance should be re-checked at regular intervals on a sample of milled grain. The milledsample shall meet the specifications given in Table 1.