ISO 16750-3 pdf download

ISO 16750-3 pdf download Road vehicles — Environmental conditions and testing for electrical and electronic equipment — Part 3: Mechanical loads

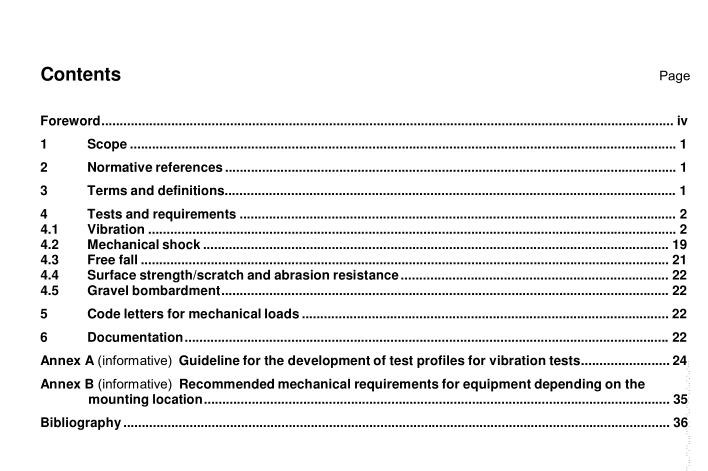

This part of ISO 16750 applies to electric and electronic systems/components for road vehicles. This part ofISO 16750 describes the potential environmental stresses, and specifies tests and requirementsrecommended for the specific mounting location on/in the vehicle.This part of ISO 16750 describes the mechanical loads

2 Normative references

The following referenced documents are indispensable for the application of this document. For datedreferences, only the edition cited applies. For undated references the latest edition of the referenceddocument (including any amendments)applies

ISO 16750-1,Road vehicles – Environmental conditions and testing for electrical and electronicequipment- Part 1: General

ISO 16750-4,Road vehicles – Environmental conditions and testing for electrical and electronicequipment- Part 4: Cimatic loads

IEC 60068-2-6, Environmental testing 一 Part 2: Tests – Test Fc: Vibration (sinusoidal)

IEC 60068-2-14, Environmental testing — Part 2: Tests – Test N: Change of temperature

IEC 60068-2-29, Environmentaltesting 一 Part 2: Tests – Test Eb and guidance: Bump

IEC 60068-2-32, Environmental testing – Part 2: Tests – Test Ed: Free fall

IEC 60068-2-64,Environmental testing — Part 2: Test methods – Test Fh: Vibration, broad-band random(digital control) and quidance

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 16750-1 apply.

4Tests and requirements

4.1 Vibration

4.11 General

The vibration test methods specified consider various levels of vibration severities applicable to on-boardelectrical and electronic equipment. It is recommended that vehicle manufacturer and supplier choose the testmethod, the environmenta temperature and vibraton parameters depending on the specific mountina location.

The specified values apply to direct mounting in defined mounting locations. The use of a bracket for mountingcan result in hicher or lower loads. lf the device under test (DUT) is used in the vehicle with a bracket, then alvibration and mechanical shock testing shall be done with this bracket.

Carry out the vibration test with the DUT suitably mounted on a vibration table. The mounting method(s) usedshall be noted in the test report. Carry out the frequency variation by logarithmic sweeping of0,5 octave/minute for sinusoidal tests and the sinusoidal part of sine on random tests. The obiective of therecommended vibration tests is to avoid malfunctions and breakage mainly due to fatigue in the field. Testingfor wear has special requirements and is not covered in this part of ISO 16750.

Loads outside the designated test frequency ranges shall be considered separately.

NOTEDeviations from the load on the DUT can result if vibration testing is carried out in accordance with this part of ISO 16750 on a heavy and bulky DUT, as mounting rigidity and dynamic reaction on the vibrator table excitation aredifferent compared to the situation in the vehicle. This deviation can be minimized by applying the average control method(see Annex A).