ISO 15841 pdf download

ISO 15841 pdf download Dentistry — Wires for use in orthodontics

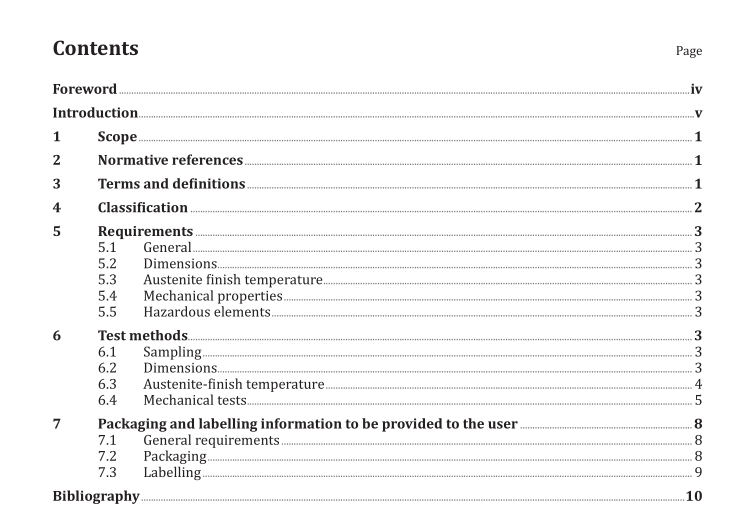

Scope

This lnternational Standard specifies requirements and test methods for wires to be used in fixed andremovable orthodontic appliances. lt includes preformed orthodontic archwires but excludes springsand other preformed components.

This International Standard gives detailed requirements concerning the presentation of the physica.and mechanical properties of orthodontic wires, the test methods by which they can be determined, andpackaging and labelling information.

2 Normative references

The following documents,in whole or in part,are normatively referenced in this document and areindispensable for its application. For dated references, only the edition cited applies. For undatedreferences, the latest edition of the referenced document (including any amendments) applies.

ISO 1942, Dentistry- Vocabulary

SO 6892-1, Metallic materials – Tensile testing – Part 1: Method of test at room temperature

ASTM F2082, Standard Test Method for Determination of Transformation Temperature of Nicke-TitaniumShape Memory Alloys by Bend and Free Recovery

3 Terms and definitions

For the purposes ofthis document, the terms and definitions given in ISO 1942 and the following apply.

3.1

austenite-finish temperature

af

temperature at which the metallurgical transformation from the low-temperature martensite phase tothe high-temperature austenite phase is completed

3.2force deflection rateEoincrement of load to produce a unit increment of deflection in the proportional region, expressed inN/mm (e.g.used in the bend test)

3.3descriptorcode to identify the nominal dimension(s) in thousandths of an inch without unit designation, inaccordance with accepted orthodontic practice

3.4

diagonal

largest cross-sectional dimension of a rectangular wire

Note 1 to entry: See Figure 1.

3.5

multistrand wire

orthodontic wire fabricated from two or more individual strands of wire that may be twisted, braided or made into a co-axial wire

3.6

offset bending force

F S(0,1)

force measured at a permanent deflection of 0,1 mm during loading in the bend test

3.7

height

smallest cross-sectional dimension of a rectangular wire

Note 1 to entry: See Figure 1.

3.8

width

larger of the height and width dimensions of a rectangular wire

Note 1 to entry: See Figure 1.

4? Classification

For the purposes of this document, wires are classified on the basis of their elastic behaviour.

a) Type 1 wires: wires displaying linear elastic behaviour during unloading at temperatures up to 50 °C.

b) Type 2 wires: wires displaying nonlinear elastic behaviour during unloading at temperatures up to 50 °C.

5 Requirements

5.1 General

The manufacturer shall declare the following properties, which, when tested in accordance with the test methods described in Clause 6, shall be within the ranges stated by the manufacturer.

5.2 Dimensions

Each cross-sectional dimension (diameter, width, height and diagonal, as applicable) of the wire shall be stated to the nearest 0,01 mm. For multistrand wires, the dimensions shall be the internal dimensions of a tube that would just contain the wire.