IEC TS-61370 pdf download

IEC TS-61370 pdf download Steam turbines -Steam purity

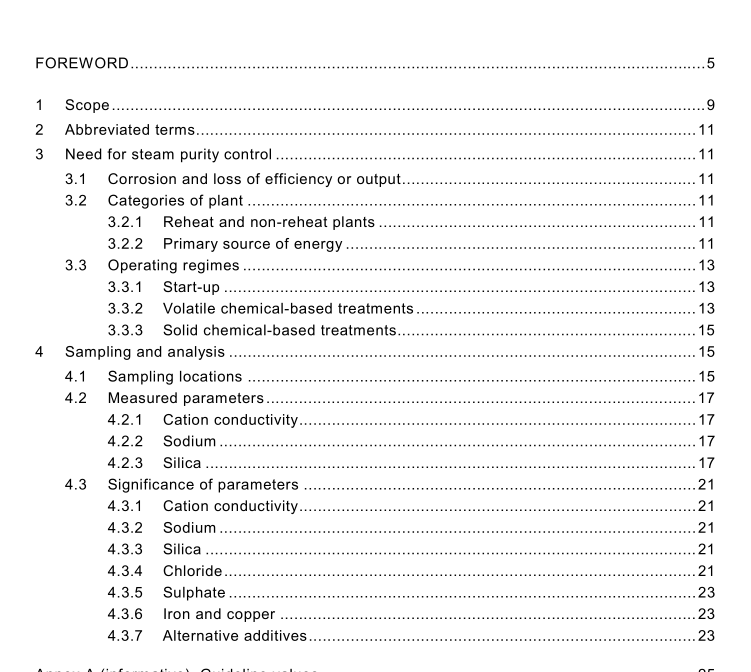

1 Scope

This technical specification describes the importance of the chemical characteristics of steamsupplied to steam turbines and the need to prevent corrosion and deposition in steam space, inorder to minimize the risk of turbine corrosion failures or loss of efficiency or output. Thesignificance of relevant chemical parameters, mostly related to impurity levels, is discussed interms of types of plant and chemistry operating regimes.

This specification is applicable to turbines of all electrical output rating and any exhaustcondition,i.e. condensing or back pressure.However,the range of application’ in termsof output rating or steam pressure is dictated by economic factors such as the relative cost ofmonitoring equipment and turbine plant. It is designed for new plant,but may be adaptedfor use on existing plant.

The limits described in this specification are specifically designed to protect the steam turbine.The user should also be aware of steam purity requirements imposed by other considerationssuch as components of the boiler or steam generator.

This specification is applicable to steam turbines driven from any source,except geothermalplants in which the turbine is fed direct from the geothermal sources.

After the initial start of the turbine it may take some months for best achievable chemistry to bereached.This tends to be achieved sooner for some parameters (sodium, cation conductivity)than for others (silica,iron,copper). It is therefore recognized that during commissioning, itmay be difficult to meet normal targets, but a steady improvement should be observed as thesteam cleans up.

Annex A provides recommended guidelines for this specification and verification of thechemical purity of steam entering a steam turbine,in order to maintain the integrity andefficiency of the turbine. The limits stated are not intended to be mandatory, but to be used asthe basis for local instructions for individual plant.Verification is addressed as the selection ofappropriate sampling locations and continuously or intermittently measured parameters.

2Abbreviated terms

For the purposes of this technical specification,

the following abbreviated terms are used:AVT

all volatile treatment

BWRboiling water reactorc.con cation conductivityc

Tcaustic treatment

EPTequilibrium phosphate treatment

FACflow accelerated corrosion

Iwc lnternational water ConferenceoToxygenated treatment

PTphosphate treatment

PWRpressurized water reactorNeed for steam purity control

3.1corrosion and loss of efficiency or output

High purity steam is required to ensure steam turbine operation with a high degree ofefficiency,output,and availability. Impurities can form deposits,which can lead to lossof efficiency or output or to corrosion. Corrosion can potentially lead to total failure of rotatingcomponents. Conditions in expanding steam are such that even a low concentration of animpurity can coexist with a small quantity at high concentration in moisture over a narrow rangeof temperature and pressure conditions,which may coincide with the surface of a turbinecomponent. lt is therefore desirable to minimize the content of impurities. The levelsrecommended in this specification are established as achievable,measurable and consistentwith a high level of efficiency, output and availability.

3.2Categories of plant

3.2.1 Reheat and non-reheat plants

The live steam limits are applicable to machines both with and without reheat.However,the different implications for impurities in these two types of plant should be appreciated.ln non-reheat fossil-fuel-fired machines,the temperature of the first condensation withinthe low-pressure (LP) stages tends to be at a higher temperature than in units with reheat.Thus, the associated risk of corrosion tends to be higher. In units with reheat,there isa tendency for some species to deposit in the reheater and for a slightly better standard ofpurity to be expected in hot reheat ‘steam than in live steam.

3.2.2Primary source of energy

Tables A.1 to A.3 do not distinguish between primary sources of energy, i.e. whether fossil-fuel-fired or nuclear. However, PWR and BWR plants differ in that steam enters the turbine insaturated condition.Also, some BWR systems operate under an enforced oxygenated neutralcondition similar to the OT option for feedwater treatment.