IEC 62420 pdf download

IEC 62420 pdf download Concentric lay stranded overhead electrical conductors containing one or more gap(s)

The surface of the conductor shall be free from all imperfections visible to the unaided eye (normal corrective lenses accepted), such as nicks, indentations, etc., not consistent with good commercial practice.

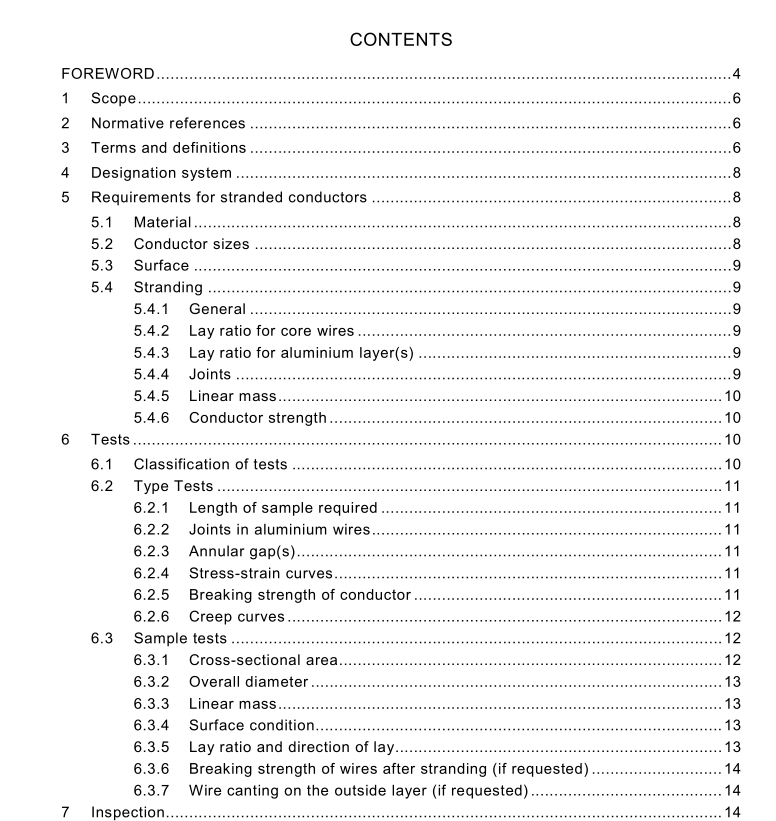

5.4 Stranding

5.4.1 General All wires of the conductor shall be concentrically stranded. Before stranding, aluminium and core wires shall have approximately uniform temperature. Adjacent wire layers shall be stranded with reverse lay directions. The direction of lay of the external layer shall be right-hand except when specifically indicated in the purchase order.

5.4.2 Lay ratio for core wires The lay ratios for the zinc-coated (galvanised) steel or aluminium-clad wire layers shall be as follows:

a) the lay ratio for the six-wire layer of the core shall be not less than 1 6 nor more than 26;

b) the lay ratio for subsequent core layers shall be not less than 1 4 nor more than 22. The lay ratio of subsequent layer(s) shall be not greater than the lay ratio of the core layer immediately beneath it. All core wires shall lie naturally in their position in the stranded core, and where the core is cut, the wire ends shall remain in position or be readily replaced by hand and then remain approximately in position.

5.4.3 Lay ratio for aluminium layer(s)

The lay ratios for the aluminium layer(s) shall be as follows:

a) the lay ratio for the outside layer of aluminium wires shall be not less than 1 0 nor more than 1 4;

b) the lay ratios for the inner layers of aluminium wires shall be not less than 1 0 nor more than 1 6;

c) the lay ratio of any aluminium layer shall be not greater than the lay ratio of the aluminium layer immediately beneath it. Aluminium wires composing the outside layer of the conductor shall lie naturally in their position, and where the conductor is cut, they shall remain in position or be readily replaced by hand and then remain approximately in position.

5.4.4 Joints

There shall be no joints of any kind made in the core wire or wires during stranding.

There shall be no joints in the finished aluminium wire prior to stranding. During stranding, no aluminium wire welds shall be made for the purpose of achieving the required conductor length.

Joints are permitted in aluminium wires unavoidably broken during stranding, provided such breaks are not associated with either inherently defective wire or with the use of short lengths