IEC 62011-2 pdf download

IEC 62011-2 pdf download Insulating materials – Industrial, rigid, moulded, laminated tubes and rods of rectangular and hexagonal cross-section, based on thermosetting resins for electrical purposes – Part 2: Methods of test

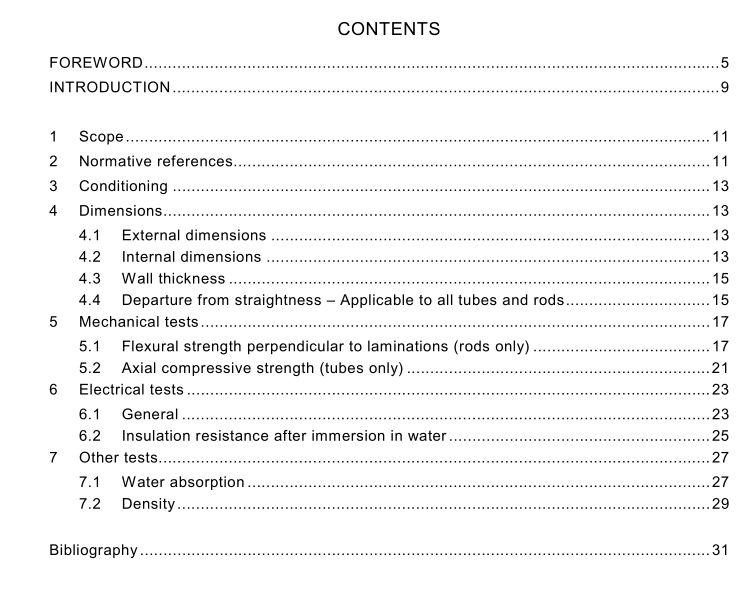

1 scope

This part of lEC 62011 deals with the test methods for industrial,rigid,moulded, laminatedtubes and rods of rectangular and hexagonal cross-section, based on thermosetting resins forelectrical purposes.

2 Normative references

The following referenced documents are indispensable for the application of this document.Fordated references,only the edition cited applies. For undated references,the latest edition ofthe referenced document (including any amendments) applies.

IEC 60167:1964,Methods of test for the determination of the insulation resistance of solidinsulating materials

IEC 60212:1971,Standard conditions for use prior to and during the testing of solid electricalinsulating materials

IEC 60243-1:1998,Electric strength of insulating materials – Test methods – Part 1: Tests atpower frequencies

IEC 60296:1982,Specification for unused mineral insulating oils for transformers andswitchgear

IEC 62011-3(all parts), Insulating materials – Industrial,rigid,moulded,laminated tubes androds of rectangular and hexagonal cross-section, based on thermosetting resins for electricalpurposes – Part 3: Specifications for individual materials

ISO 62:1999,Plastics – Determination of water absorption

ISO 178:2001,Plastics – Determination of flexural propertiesISO 604:2002,Plastics – Determination of compressive properties

ISO 1183:1987,Plastics – Methods for determining the density and relative density of non-cellular plastics

ISO 5893:2002,Rubber and plastics test equipment – Tensile, flexural and compression types(constant rate of traverse)- Specification

3 Conditioning

Unless otherwise specified, test specimens shall be conditioned immediately prior to testing forat least 24 h in standard atmosphere B according to lEC 60212 at a temperature of 23 iC±2 K, and a relative humidity of (50土 5)%.

Unless otherwise specified,each specimen shall be tested in the conditioning atmosphere orthe tests shall commence within 3 min of removal of each specimen from the conditioningatmosphere.

4Dimensions

4.1 External dimensions4.1.1 Test apparatus

The external dimensions of rectangular tubes and rods and the distance between faces of ahexagonal rod shall be determined using an instrument capable of measuring with an accuracyof t0,02 mm or better. This may be either a screw type micrometer gauge or a slide gauge(Vernier caliper).In the case of a screw type micrometer, the measuring faces shall be 6 mm to8 mm in diameter, flat to within 0,01 mm and parallel to within 0,003 mm.

Any other means of measurement which can be shown to give the same results is permissiblebut, in case of dispute, the screw type micrometer or the slide gauge shall be used.

4.1.2 Procedure

4.1.2.1 External dimensions of rectangular and square sections

In the ‘as received’ condition, measure the two dimensions (distance between opposite faces ofthe rod or tube) in three different planes perpendicular to the axis. In general, the measure-ments shall be made in the middle and at each end of the tube or rod, but not less than 20 mmfrom the ends.Record the three results obtained for each of the two dimensions to the nearest0,02 mm.

4.1.2.2 External dimensions of hexagonal sections

In the ‘as received’ condition, measure the distances between opposite faces of the rod in threedifferent planes perpendicular to the axis. In general, the measurements shall be made in themiddle and at each end, but not less than 20 mm from the ends.Record the three resultsobtained for each of the three dimensions to the nearest 0,02 mm.