IEC 60034-11 pdf download

IEC 60034-11 pdf download Rotating electrical machines – Part 11: Thermal protection

1Scope

This part of lEC 60034 specifies requirements relating to the use of thermal protectors andthermal detectors incorporated into the stator windings or placed in other suitable positions ininduction machines in order to protect them against serious damage due to thermal overloads.lt applies to machines manufactured in accordance with lEC 60034-12 with the voltage limitsspecified in lEC 60034-12. The protection of bearings and other mechanical parts is notincluded.

NOTE 1 Although temperature values given in this standard are higher than those specified in IlEC 60034-1, theyare not in conflict.

NOTE 2 Additional requirements may apply to particular motor types such as those used in household appliances,or for motors used in explosive atmospheres.

2Normative references

The following referenced documents are indispensable for the application of this document.For dated references, only the edition cited applies. For undated references, the latest editionof the referenced document (including any amendments) applies.

IEC 60034-1:2004,Rotating electrical machines – Part 1 : Rating and performance

IEC 60034-12:2002,Rotating electrical machines – Part 12: Starting performance of single-speed three-phase cage induction motors

Terms and definitions

For the purposes of this part of lEC 60034, the following terms and definitions apply.

3.1

thermal protection

protection of windings of a machine against excessive temperature resulting from conditionsof overload or loss of cooling

3.2

thermal protection system

system for the protection of a machine winding against excessive temperature resulting fromconditions of overload or loss of cooling by means of either thermal protector(s) or thermaldetector(s)

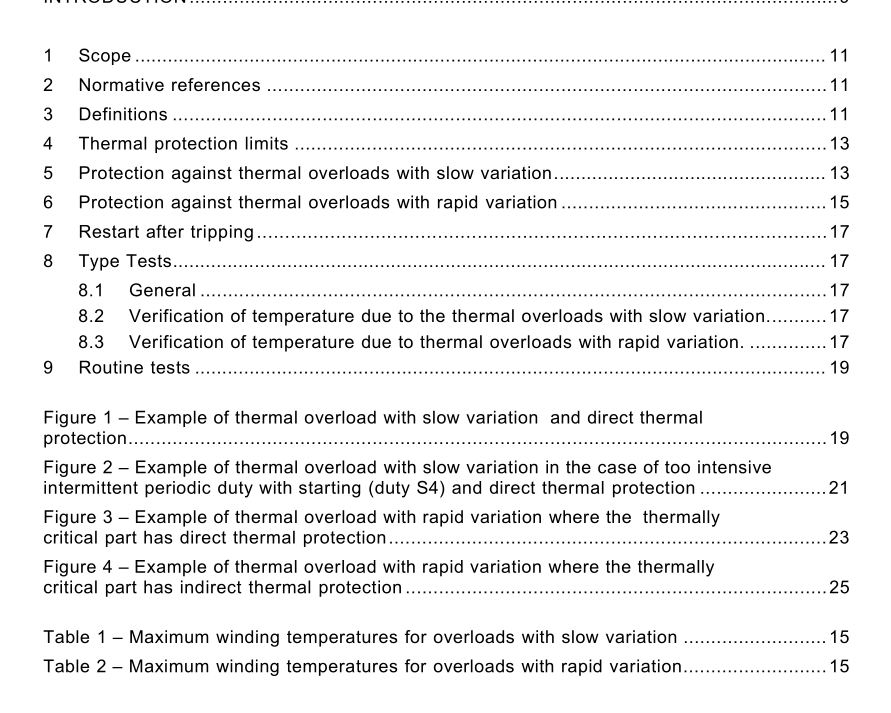

4 Thermal protection limits Machines shall be capable of operating at rated output and at all operating conditions according to IEC 60034-1 without activation of the thermal protection device. The thermal protection device shall limit the winding temperature in accordance with Clauses 5 or 6.

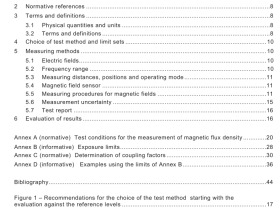

5 Protection against thermal overloads with slow variation When subjected to an overload or other misuse condition causing overheating with slow variation, the protection system shall operate to prevent the temperature of the machine winding from exceeding the values in Table 1 .

The winding temperature shall be determined by the resistance method in accordance with the requirements of 8.6.2 of IEC 60034-1 .

NOTE 1 The limit values Table 1 exceed the thermal classification and thus will reduce the lifetime of the motor, if the motor is operated over a longer period of time with these values.

NOTE 2 Some of the ways in which a thermal overload with slow variation may be caused are:

• Defects in ventilation or the ventilation system due to excessive dust in the ventilation ducts, or dirt on windings or frame cooling ribs, etc.

• An excessive rise in ambient temperature or the temperature of the cooling medium.

• Gradual increasing mechanical overload.

• Prolonged voltage drop, over-voltage or unbalance in the machine supply.

• Excessive duty on a motor rated for intermittent duty.

• Frequency deviations.

NOTE 3 The maximum temperature limits are based on experience taking into account factors such as ambient temperature, variations in supply voltage and normal requirements for starting motors.

6 Protection against thermal overloads with rapid variation

When a thermal overload with rapid variation is applied to the machine, the thermal protection system shall operate to prevent the temperature of the machine winding from exceeding the values given in Table 2.