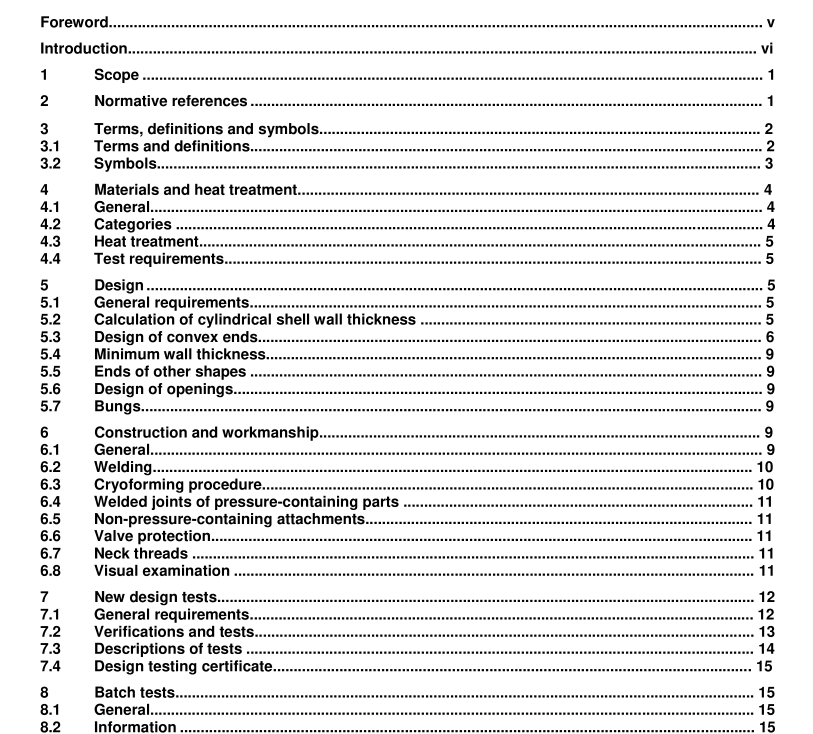

BS ISO 18172-2 pdf download

BS ISO 18172-2 pdf download Gas cylinders — Refillable welded stainless steel cylinders — Part 2: Test pressure greater than 6 MPa

4 Materials and heat treatment

4.1 General

4.1.1 Materials of shells and end pressings shall be stainless steels in a condition suitable for pressing or drawing and welding, and shall conform to ISO 9328-7.

4.1.2 Grades of steel used for the cylinder manufacture shall be compatible with the intended gas service (e.g. corrosive gases, embrittling gases), in accordance with ISO 1 1 1 1 4-1 . Due to the scope of this part of ISO 1 81 72, which permits tensile strengths up to 1 1 00 MPa, particular care shall be taken when designing hydrogen gas cylinders.

4.1.3 There is a risk of sensitization to intergranular corrosion resulting from the hot processing of austenitic and duplex stainless steels. If any heat treatment was done during manufacturing, an intergranular corrosion test in accordance with 7.3.3 shall be carried out. m

4.1.4 The manufacturer shall be able to guarantee cylinder steel casting traceability for each pressure- retaining part of the cylinder.

4.1.5 All parts welded to the cylinder shall be made of compatible material with respect to the weldability.

4.1.6 The cylinder manufacturer shall obtain and provide material certificates of the ladle analysis from the steel manufacture of the steel supplied for the construction of the pressure-retaining parts of the cylinder and for the welding consumables.

4.1.7 Some grades of stainless steel may be susceptible to environmental stress corrosion cracking (SCC). A check shall be made of the material standard to ensure that the selection of material is compatible with the intended service. Special precautions shall be taken, e.g. by carrying out a post-processing SCC test or by using a grade of material more resistant to SCC. No special precautions shall compromise any other requirements in this part of ISO 1 81 72.

4.1.8 The welding consumables shall be such that they are capable of giving consistent welds. The strength characteristics of the welds shall not be less than those considered in the design and/or calculations.

4.2 Categories The following three broad categories of stainless steels are recognised:

⎯ ferritic;

⎯ austenitic;

⎯ ferritic/austenitic (duplex).

The steels used shall be in accordance with ISO 9328-7.

4.3 Heat treatment

4.3.1 For cylinders subjected to cold forming or cryoforming processes, heat treatment of the preform component part is not required. Cryoformed cylinders shall not be subjected to any subsequent heat treatment or to additional heat application, such as welding.

4.3.2 Raw materials used for the manufacture of pressure-retaining parts of the cylinders shall be annealed for ferritic steels, or solution annealed for austenitic and duplex steels (see ISO 9328-7:2004, Annex C).

4.3.3 The cylinder manufacturer shall obtain and provide certificates for the heat treatment of all parts covered by 4.3.2 that are used for the construction of the gas cylinders.

4.3.4 The cylinder manufacturer shall maintain records of any heat treatment carried out.

4.4 Test requirements

The material of the finished cylinders shall satisfy the requirements of Clause 7.

5 Design

5.1 General requirements

5.1.1 The calculation of the wall thickness of the pressure-containing parts shall be related to the yield stress of the parent material.