ASME B16.25 pdf download

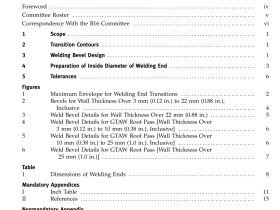

ASME B16.25 pdf download Buttwelding Ends 1 SCOPE 1.1 General This Standard covers the preparation of buttweldingends of piping components to be joined into a pipingsystem by welding. lt includes requirements for weldingbevels, for external and internal shaping of heavy-walcomponents,and for preparation of internal ends(including dimensions and tolerances). Coverageincludes preparation for joints with the following: (a) no backing rings (b)...

ASME B16.26 pdf download

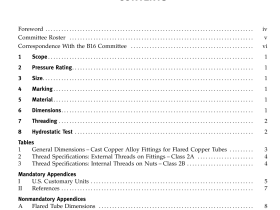

ASME B16.26 pdf download Cast Copper Alloy Fittings for Flared Copper Tubes 1 SCOPE 1.1 General This Standard establishes specifications for cast copper alloy fittings and nuts used with flared seamlesscopper tube conforming to ASTM B 88 (water and general plumbing systems). Included are requirements forthe following: (a) pressure rating (b) size (c) marking(d) material(e) dimensions(f) threading(g) hydrostatic testing 1.2...

ASME B16.36 pdf download

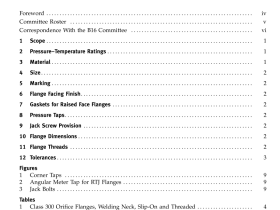

ASME B16.36 pdf download Orifice Flanges 3.3 Plugs Pressure retaining plugs shall conform to ASME B16.11, unless otherwise agreed between pur- chaser and manufacturer. Plug material shall be at least as corrosion resistant as the corresponding flange material. 4 SIZE Orifice flange sizes are indicated by the nominal pipe size to which they are attached. Only those listed in Tables...

ASME B16.38 pdf download

ASME B16.38 pdf download Large Metallic Valves for Gas Distribution Manually Operated, NPS 2 1 / 2 (DN 65) to NPS 12 (DN 300), 125 psig (8.6 bar) Maximum 2.7 Gas Resistance All materials, including lubricants and sealants, shall be resistant to deterioration when exposed to fuel gases such as listed in para. 1.2. 2.8 Temperature Resistance The materials used...

ASME B16.39 pdf download

ASME B16.39 pdf download Malleable Iron Threaded Pipe Unions Classes 150, 250, and 300 The reference point for the internal product thread is the starting end of the fitting, providing the chamfer does not exceed the major diameter of the internal thread. When a chamfer on the product thread exceeds this limit, the reference point becomes the last thread scratch...

ASME B16.42 pdf download

ASME B16.42 pdf download Ductile Iron Pipe Flanges and Flanged Fittings Classes 150 and 300 6 MATERIALS 6.1 Castings Ductile iron castings covered by this Standard shallconform to ASTM A395.The castings shall not berepaired byplugging, welding, brazing, orimpregnation. 6.2 Bolting Bolting listed in paras. 6.21 and 6.22 is recommendedto be used in flanged joints covered by this Standard.Bolting of other...

ASME B16.48 pdf download

ASME B16.48 pdf download Line Blanks 3.2.2 System Pressure Testing. Line blanks may be subjected to system tests at a pressure not to exceed 1.5 times the 38°C (100°F) rating rounded off to the next higher 1 bar (25 psi) increment. Testing at any higher pressure is the responsibility of the user, taking into account the requirements of the applicable...

ASME B16.51 pdf download

ASME B16.51 pdf download Copper and Copper Alloy Press-Connect Pressure Fittings 9.2 Out-of-Roundness of Fitting End (P or FTG) Maximum out-of-roundness ofthe press-connectfitting ends, dimensions A and F, shall not exceed 1% of the maximum corresponding diameters shown in Table 9.1-1. The average of the maximum and minimum diameters shall be within the dimensions shown in Table 9.1-1. 9.3 Inside...

ASME B16-1 pdf download

ASME B16-1 pdf download Gray Iron Pipe Flanges and Flanged Fittings Classes 25, 125, and 250 Equipment shall be designed to produce wall thick- nesses given in the tables. Wall thickness at no point shall be less than 87.5% of the thickness given in the tables. 7.2 Facing (a) Classes 25 and 125 gray iron flanges and flanged fittings shall...

ASME B18.2.1 pdf download

ASME B18.2.1 pdf download Square, Hex, Heavy Hex, and Askew Head Bolts and Hex, Heavy Hex, Hex Flange, Lobed Head, and Lag Screws (Inch Series) 2 GENERAL DATA FOR BOTH BOLTS AND SCREWS 2.1 Heads 2.1.1 Top of Head. Top of head shall be full form and chamfered, withthe diameterofchamfercircle equal to the maximum width across flats, on square or...