ASME HST-4 pdf download

ASME HST-4 pdf download Performance Standard for Overhead Electric Wire Rope Hoists

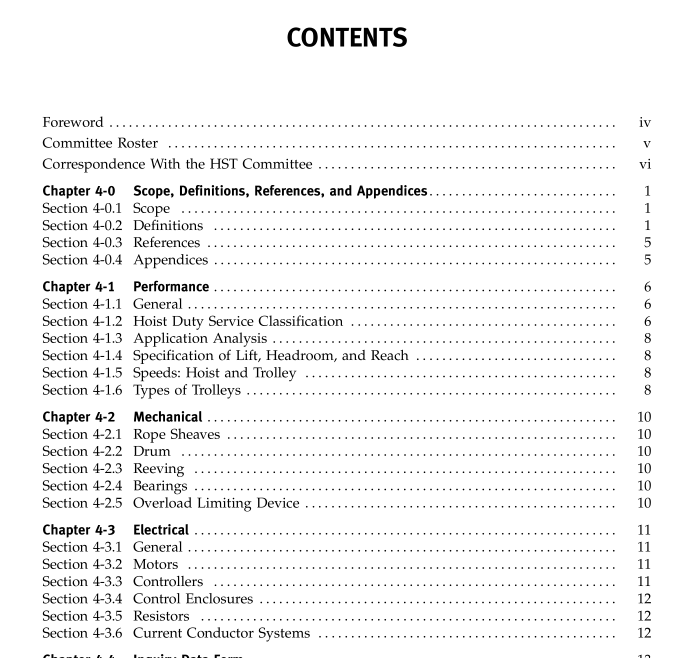

SECTION 4-0.1 SCOPE

(a) This Standard establishes performance requirements for electric wire rope hoists for vertical liftingservice involving material handling of freely suspended(unguided)loads using wire rope with one of the following types of suspension:

(1) lug

(2) hook

(3) trolley(4) base or deck mounted (does not include basemounted winches of the type covered by ASME B30.7(5) wall or ceiling mounted (does not include basemounted winches of the type covered by ASME B30.7(b) This Standard is applicable to hoists manufacturedafter the date on which this Standard is issued. ThisStandard is not applicable to

(1) damaged or malfunctioning hoists

(2) hoists that have been misused or abused(3) hoists that have been altered without authorization of the manufacturer or a qualified person

(4) hoists used for the purpose of lifting or loweringpeople

(5) hoists used for the purpose of drawing both theload and the hoist up or down the hoist’s own wire rope(6) hoists used for marine and other applicationsas required by the U.S. Department of Defense (DOD)(c) The requirements of this Standard shall be appliedtogether with the requirements of ASME B3016 Pleasealso refer to ASME B3016 for requirements pertainingto marking,construction, and installation; inspectiontesting, and maintenance; and operation.

SECTION 4-0.2 DEFINITIONS

abnormal operafing conditions: environmental conditionsthat are unfavorable harmful. or detrimental to the oper.ation of a hoistsuch as excessively high or low ambienttemperatures; exposure to weather, corrosive fumes, odust-laden or moisture-laden atmospheres: andhazardous locations ambient temnperature: the temperature of the atmospheresurrounding the hoist.

base or deck mounted: a type of mounting where the hoistis mounted to the top side of a horizontal supportingsurface.

beam: an overhead standard structural or specially fabricated shape on which the trolley operates.

block, load: the assembly ofhook or shackle, swivel, bearing,pins, sheaves, and frame suspended by the ropeThis shall include all appurtenances reeved into thehoisting rope.

brake: a device, other than a motor, used for retardingor stopping motion by friction or power means.brake, holding: a friction brake for a hoist that is automatically applied and prevents motion when power is offbrake, mechanical load: an automatic type of friction brakeused for controlling loads in a lowering direction. Thisunidirectional device requires torque from the motor tolower a load but does not impose additional load onthe motor when lifting a load.

braking, control: a method of controlling speed by remov-ing energy from the moving body or by impartingenergy in the opposite direction.

braking, countertorgwe (plugging): a method of controllingspeed by applying a variable motor torque in the direction opposite to the direction that the motor is rotatingdue to being overhauled by the load.

braking, dynamic: a method of controlling speed by usingthe motor as a generator, with the energy being dissipated by resistance.

braking, eddy current: a method of controlling or reducingspeed by means of an electrical induction load brake.braking, mechanical: a method of controlling or reducingspeed by friction.

braking, regenerative: a method of controlling speed inwhich the electrical energy generated by the motor isfed back into the power system.