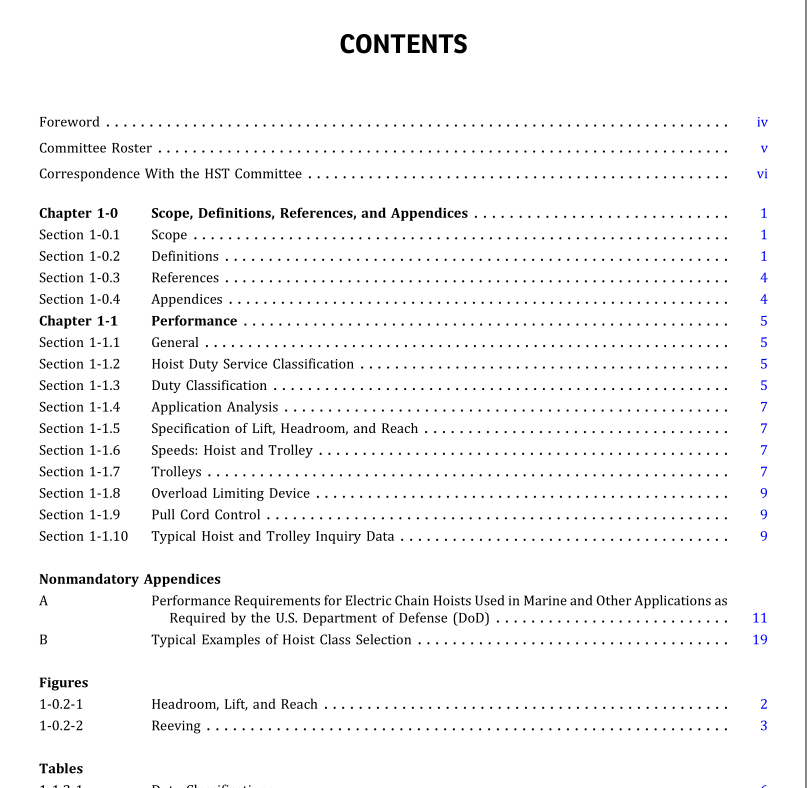

ASME HST-1 pdf download

ASME HST-1 pdf download Performance Standard for Electric Chain Hoists

SECTION 1-1.1: GENERAL

Allequipmentselectedin accordance with this Standardis designed to perform satisfactorily when used in accordance with Chapters 16-2 through 16-4 of ASME B3016and used within the rated load and hoist duty service clas-sification. All equipment shall provide speeds, lifts, andheadroom in accordance with the manufacturer’s speci-fications or to specifications agreed upon by the manufacturer and the user.

SECTION 1-1.2: HOIST DUTY SERVICE

CLASSIFICATION

Service conditions have an important influence on theperformance ofthe wearing parts of a hoist, such as gears.bearings,load chain, sprockets,electrical equipmentbrake linings, load and lift limiting devices, and wheelsCareful consideration of the hoist duty service classifications described in this Section will enable the user to eval-uate the application, and to obtain a hoist designed foroptimum performance and minimum maintenance.Ifdoubt exists regarding hoist selection, the hoist suppliershould be consulted. Many factors enter into the selectionof the proper hoist to perform a given function. Hoistingequipment consists of both mechanical and electricalcomponents and both must be considered when analyzingthe service the hoist must perform.

The factors thatinfluence the mechanical and electricaperformance of any hoist include the following:(a) Load Distribution. The actual distribution orproportion of full and partial loads to be handled bythe equipment,including lifting devices, has an importanteffect on the life of power transmission components. Forexample, ball-bearing life varies according to the cube ofthe load. A 2-ton (1 814.4-kg) hoist operated at a meaneffective load of 1 ton (907.2 kg) will have a ball-bearinglife eight times that of the same hoist used steadily at itsrated load.

(b) Operational Time, Operational time is the totalrunning time of the hoist per hour or per work period.(c) Work Distribution. This is determined by whetherthe operational time is uniformly distributed over thework period or concentrated in a short time span.Work distribution generally does not appreciably affectmechanical wear, but does materially affect the electricalcomponents such as motors, brakes, and controls. For example, a hoist motor designed to operate 15 min outof each hour of an 8-hr shift cannot handle 2 hr ofsteady run and 6 hr ofidle time even though either condi-tion only requires 2 hr of operational time per 8-hr shift(d) Number ofStarts and Stops. This directly affects allelectromechanical devices, such as motors, contactorsbrakes, and solenoids.

(e) Repetitive Long Lowering Operations. Such opera-tions generate heat in control braking means.( Environmental Conditions. Hoist equipment isdesigned to operate in ambient temperatures between0°F(-18°C)and 104°F(40C)andin atmospheres reason-ably free from dust, moisture, and corrosive fumes unlessotherwise specified.

(g) Hazardous Locations. lfhoistsare used in hazardouslocations as defined by NFPA 70 or other special codes,modifications or additional precautions not covered bythis Standard may be required. In these locations, onlyhoists designed in a manner suitable for the conditionsencountered shall be used.