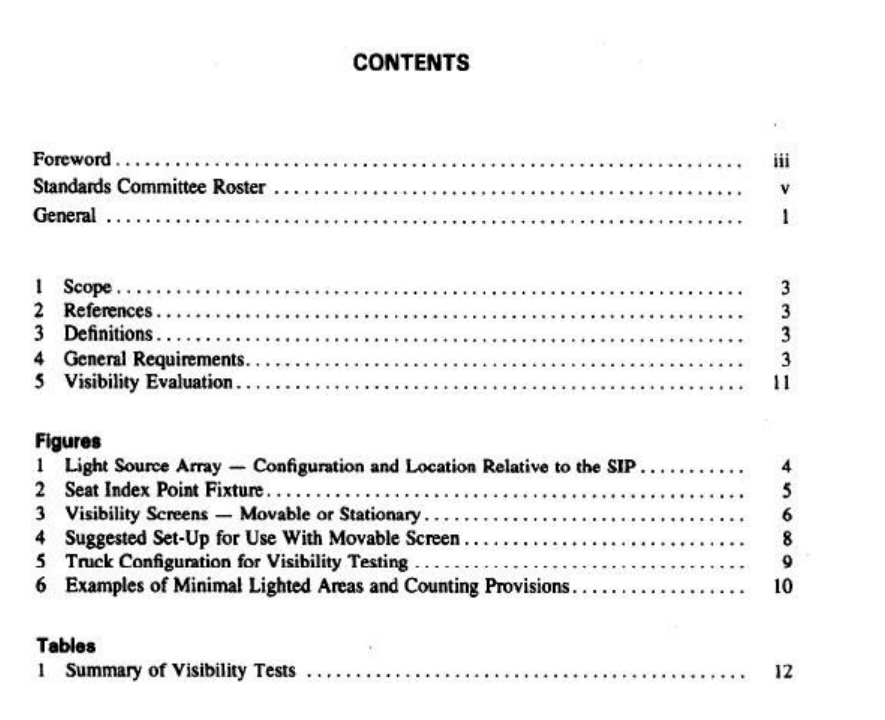

ASME B56.11.6 pdf download

ASME B56.11.6 pdf download Evaluation of Visibility from Powered Industrial 1 rucks

1 SCOPE

This Standard establishes the conditions, procedures, equipment, and acceptability criteria for evaluating vis- ibility from powered industrial trucks. It applies to intemal combustion engine powered and electric high lift, counterbalanced, sit-down rider industrial trucks up to and including 10 000 kg (22,000 lb) capacity. Visibility is evaluated by using an array of lamps, centered at the theoretical eye level of a seated operator, and observing light and shadow areas on a vertical screen in specific locations around the truck.

The light source aray simulates the normal range of position of the scated operator’s eyes with typical head movement. The light and shadow areas describe what can and can not be seen by the operator. Traveling mode visibiity is evaluated with the screen 4000 mm (157.48 in.) to the front of and to the rear of the truck. For maneuvering mode vis- ibility, the screen is positioned at 1200 mm (47.24 in.) from the truck to the front, rear, and both sides. Ac- ceptable visibility is based on measurements of dark shadows cast on the screen in each of the test conditions.

2 REFERENCES

2.1 International Organization for Standardization

ISO 5353-1978 (E), Earth-Moving Machinery Seat Index Point

ISO/TC 110/SC 2 N 258, Draft proposal April 1982, Powered lndustrial Trucks – Visibility Test Methods and Requirements

3 DEFINITIONS

Refer also to teminology in Appendix B of ASME/ ANSI B56.1. acceptable visibility – test results from a complete se- ries of tests conducted in accordance with this volume which meet or exceed the acceptability criteria estab- lished for each test condition

dark shadow an area on the screen which is not di- rectly iluminated by any of the lamps of the light source array light area – an area on the screen which is directly illuminated by at least one lamp on the light source array

light source array一a device, consisting of 26 lamps configured as shown in Fig. 1, used to provide ight from the range of positions of the operator’s eyes to a screen. The light source array can be rotated to five positions, as shown in Fig. 1, to evaluate visibility to the front, rear, left, and right.

maneuvering – refers to precise movement of the truck as it is being used to move materials, or passing objects close by, at slow speeds operator’s eye

level – a theoretical horizontal plane at 650 mm (25.59 in.) above the SIP, representing an av- erage operator

traveling一movement of the truck over relatively long uistance and upen areas a faster speeds than maneuvering

4 GENERAL REQUIREMENTS

4.1 Test Facility The visibility tests should be conducted in an area where all other sources of light can be eliminated and only light from the light source array shines on the screen