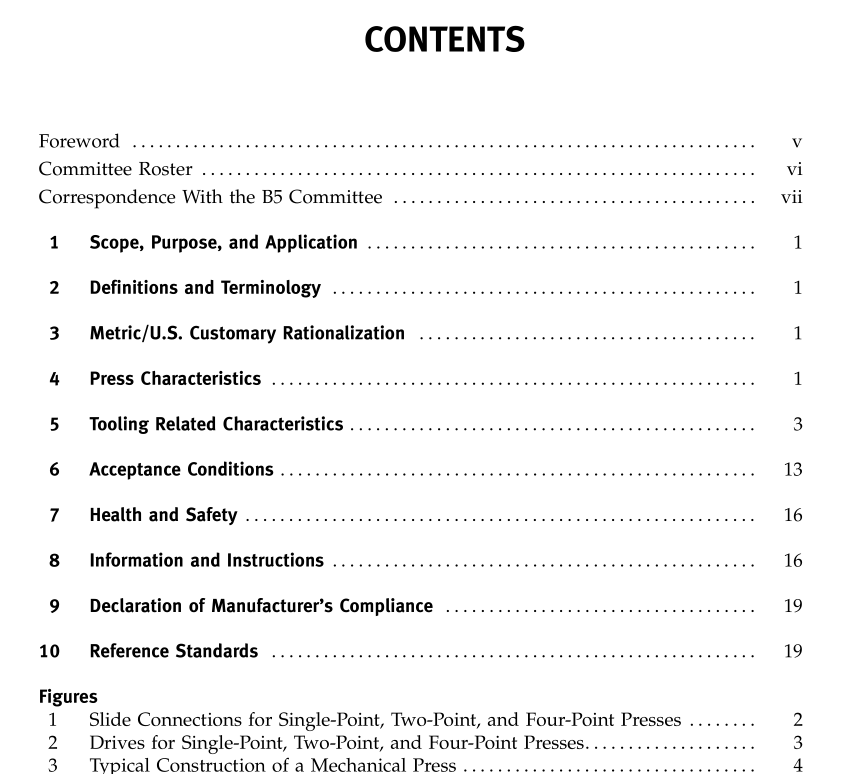

ASME B5.61 pdf download

ASME B5.61 pdf download Power Presses: General Purpose, ? Single Action, Straight Side Type

1 SCOPE, PURPOSE, AND APPLICATION

1.1 Scope

This Standard applies to hydraulic and mechanical power presses commonly referred to by the metal- working industry as General Purpose, Single Action, Straight Side Type Power Presses that, by means of dies or tooling attached to the slide and bolster, are used to shear, punch, form, or assemble metal or other materials. The following types of presses are excluded from this Standard:

(a) air (pneumatic)

(b) bench

(c) eyelet machines

(d) forging

(e) four slide machines

(f) gap frame

(g) knuckle joint

(h) multiple action

(i) multiple slide

(j) spotting

(k) transfer feed

(l) turret punching

1.2 Purpose

The purpose of this Standard is to define and describepower presses and their interface, and to permit inter-changeability of bolsters, dies, and tooling componentsbetween presses of comparable type, size, and capacity.

1.3 Application

Any power press described herein and referred toas an American National Standard Power Press shallcomply with the applicable requirements delineated inthis Standard.

2 DEFINITIONS AND TERMINOLOGY

Terms used in this Standard are defined in ASMEB5.49, Glossary of Power Press Terms.

3 METRIC/U.SCUSTOMARY RATIONALIZATION

31 Metrication

All units of dimension and capacity stated herein arein accordance with ASME B5.51M,Preferred SI Units for Machine Tools.Approximate U.S. Customary unitsare historical standards and are for reference only. Wherever used in this Standard, the unit fons denotes U.Stons.

3.2 Metric/U.S.Customary Conversion

Nonmandatory Appendix A provides conversionmultipliers applicable to this Standard.

4 PRESS CHARACTERISTICS

4.1 Rated Capacity

Standard capacity ratings shall be as specified inTable 1 (see also Fig. 1) See Nonmandatory Appendix Bfor historical comparison of capacity ratings.

4.2 Rating Points (Mechanical Power Press)

(a) Standard rating points shall be as specified in

Table 2.(b) Drive design shall be based on providing thetorque, which produces the rated press capacity at therating point (see Fig. 2).(c) Press capacity at points other than the rating point

are shown in(1) Mandatory Appendix I for presses rated at12.7 mm (% in.)(2) Mandatory Appendix II for presses rated at6.3 mm (4 in.)