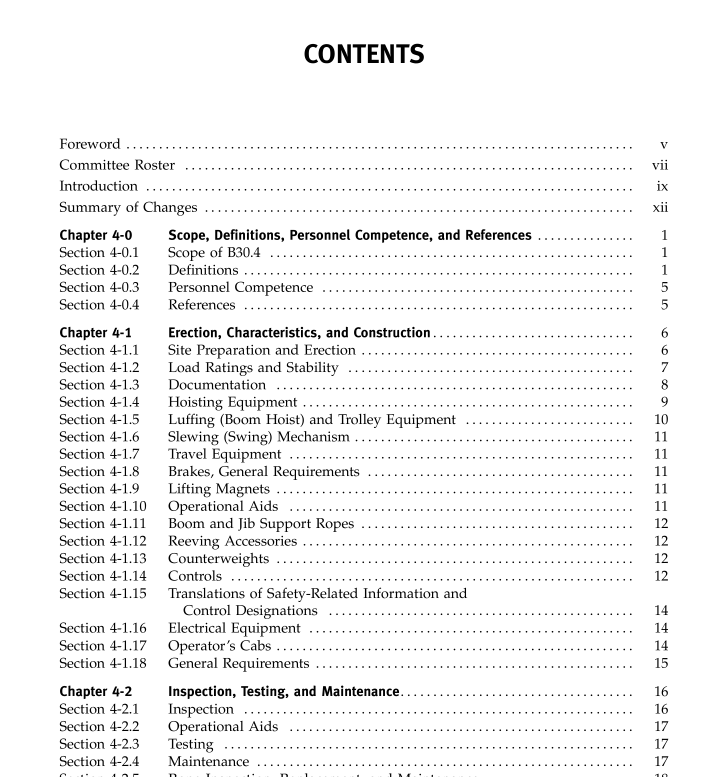

ASME B30.4 pdf download

ASME B30.4 pdf download Portal and Pedestal Cranes Safety Standard for Cableways, Cranes, Derricks, Hoists, Hooks, Jacks, and Slings

SECTION 4-0.1: SCOPE OF B30.4

Volume B30.4 includes provisions that apply to theconstruction,installation, operation, inspection, testingand maintenance of electric motor or internalcombustion engine-powered portal and pedestal cranesthat adjust operating radius by means of a boom luffingmechanism or by means of a trolley traversing a horizontal boom, that may be mounted on a fixed or traveling base, and to any variation thereof that retain thesame fundamental characteristics.

This Volume applies only to portal and pedestal cranesutilizing a drum and wire rope for hoisting and thatare used for hoisting work. The requirements for towercranes (refer to ASME B30.3),telescopic boom cranestwin boom container handling cranes, and articulatingboom cranes are not included in this Volume.

SECTION 4-0.2: DEFINITIONS

4-0.2.1 Types of Cranes

luffing crane: a crane with a boom pinned to the superstructure at its inner end and containing load-hoistingtackle at its outer end and with a hoist mechanism toraise or lower the boom in a vertical plane to changeload radius (see Figs.4-0.2.1-1 through 4-0.2.1-3).

pedestal crane: a crane consisting of a rotating superstructure with operating machinery and boom, all of whichis mounted on a pedestal (see Fig.4-0.21-1)porfal crane: a crane consisting of a rotating superstructure with operating machinery and boom, all of whichis mounted on a gantry structure, usually with a portalopening between the gantry columns or legs for trafficto pass beneath the crane. The crane may be fixed or ona traveling base (see Figs.4-0.2.1-2 and 4-0.2.1-3)

4-0.2.2 General

accessory: a secondary part or assembly of parts thatcontributes to the overall function and usefulness of amachine.

administrative or regulatory authority: governmentalagency or the employer in the absence of governmentaljurisdiction.

alteration (modification): any change in the original equipment manufacturer ‘s design configuration of the cranethat pertains to load-supporting components, load-positioning components, and other components that affectthe safe load-carrying capability of the crane (e.g., coun-terweights, holding valves), including operational aidslimit devices and other safety equipment.

axis of rotation: the vertical axis around which the cranesuperstructure rotates.

bogie: an assembly of two or more axles arranged topermit both vertical wheel displacement and an equal-ization of loading on the wheels.

boom: a member used for supporting the hoisting tacklehinged to a fixed or rotating structure or to a mastwith its outer end supported by ropes, chains, rods, orhydraulic cylinder(s).

boom point: the outward end of the load-bearing boomboom stop: a device or structure designed to limit boomtravel to its highest allowable position.

brake: a device, other than a motor, used for retardingor stopping motion by friction or power means.

braking means: a method or device for retarding or stopping motion.

buffer/bumper: an energy-absorbing device for reducingimpact when a moving boom or crane reaches the endof its permitted travel.

cab: a housing provided for the operator and containingthe crane controls.

clutch: a means for engagement or disengagement ofpower.

counferteight: weight used to supplement the weight ofthe machine in providing stability for lifting workingloads; it swings with the crane.

crane, standby: crane that is not in regular service butused occasionally or intermittently as required.

drum: the cylindrical member around which a rope iswound and through which power is transmitted to theropes.