ASME B30.28 pdf download

ASME B30.28 pdf download Balance Lifting Units Safety Standard for Cableways, Cranes, Derricks, Hoists, Hooks, Jacks, and Slings

SECTION 28-0.1: SCOPE OF ASME B30.28

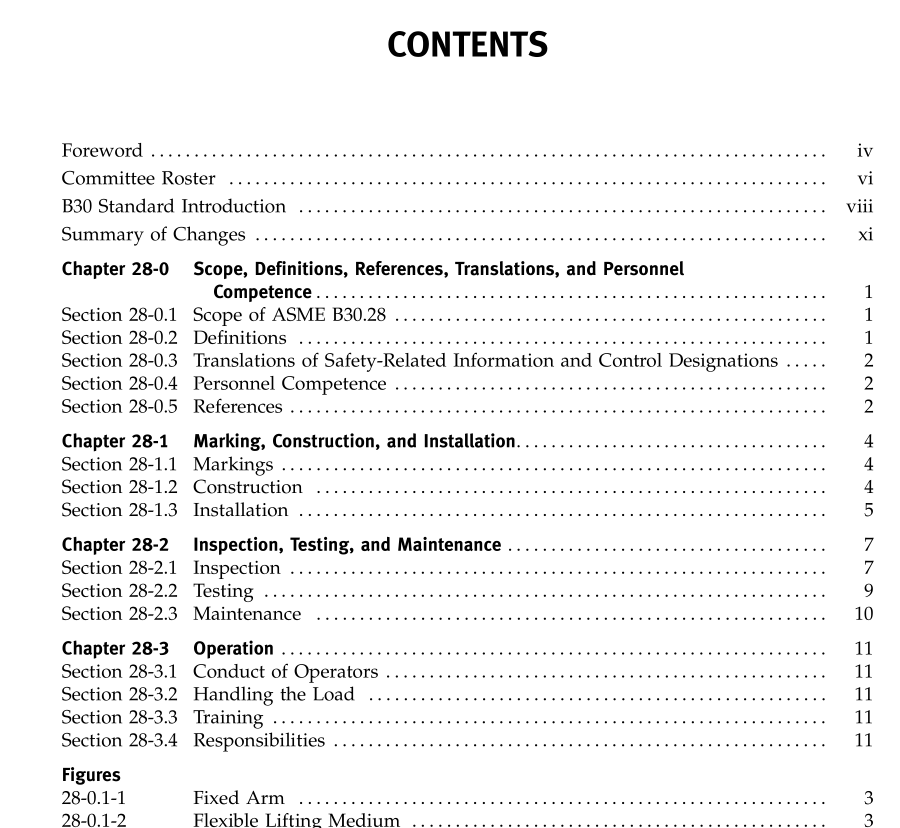

Volume B30.28 includes provisions that apply to themarking,construction, installation, inspection, testing.maintenance, and operation of balance lifting units (balancers). Balancers are distinguished by their ability tofloat the load. This Volume applies to balancers withfixed arm support (Fig. 28-0.1-1) and balancers withoverhead flexible lifting medium (Fig.28-0.1-2).ThisVolume does not apply to balancers with autonomousoperation or balancers used for lifting personnel,asthese units require additional considerations,provi-sions, and features that are not included in this Volume.

SECTION 28-0.2: DEFINITIONS

abnormal operating conditions: environmental conditionsthat are unfavorable, harmful, or detrimental to or forthe operation of balancers, such as excessively high orlow ambient temperatures, exposure to adverse weathercorrosive fumes, dust-laden or moisture-laden atmospheres,and hazardous locations.

balancer: a balance lifting unit capable of moving loadswithin the rated capacity and with the capability to floatthe load

balancer service,heauy: service that involves operationwithin the rated load limit, which exceeds normalservice.

balancer service, normal: service that involves operationwith loads at or less than 65% of rated load for not morethan 50% of the time.

balancer service, severe: service that involves normal orheavy service with abnormal operating conditions.balancer standby: balancers that are not in regular servicebut are used occasionally or intermittently, as requiredclearance: the distance from any part of the balancer tothe nearest obstruction.

end effector: a feature, device, method, or components forconnecting the load to a balancer. Also may be referred toas “receiver”or “below the hook lifting devices” (seeASME B30.20).

exposed: applies to hazardous objects not guarded orisolated (capable of being contacted inadvertently)float the load: the ability to move the load up or down,without inputs to the operational controls, by applyinga force to the load of less than 5% of the load.

hazardous (classified) locations: locations where fire orexplosion hazards may exist. Locations are classifieddepending on the properties of the flammable vaporsiquids, or gases, or combustible dusts or fibers thatmay be present and the likelihood that a flammable orcombustible concentration or quantity is present. Referto NFPA 70.

Class I locations: locations in which flammable gasesor vapors are or may be present in the air in quantitiessufficient to produce explosive or ignitable mixtures.Class II locations: locations that are hazardous becauseof the presence of combustible dust.

Class III locations: locations that are hazardous becauseof the presence of easily ignitable fibers or flyings, butin which such fibers or flyings are not likely to be insuspension in the air in quantities sufficient to produceignitable mixtures.

lifting medium: the balancer component that supportsand moves the load up and down and determines thetype of balancer.

load: the total superimposed weight on the balancerincluding any end effector devices attached to thebalancer.

load, rated: the maximum load designated by the manufacturer for which the balancer is designed and built.manual ualves: a valve for which a manual actuator isthe only means of valve actuation.

normal operating conditions: conditions during which balancers are performing functions within the scope of theoriginal design.

overload: any load greater than the rated load.qualified person: a person who, by possession of a recognized degree or certificate of professional standing,orwho by extensive knowledge, training,and experiencehas successfully demonstrated the ability to solve or