AS ISO 13007.2 pdf download

AS ISO 13007.2 pdf download Ceramic tiles—Grouts and adhesives Part 2: Test methods for adhesives

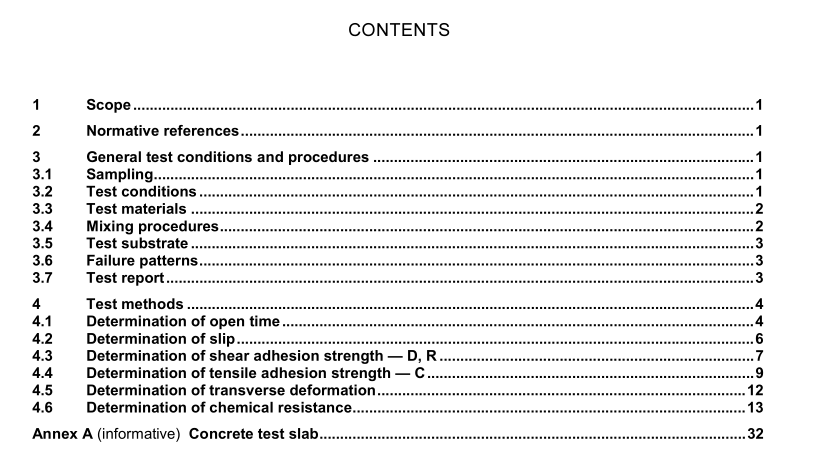

Scope

This part of ISO 13007 describes methods for determining characteristics for adhesives used in the installationof ceramic tiles.The test methods described are the following:

a) determination of open time:

b) determination of slip:

c) determination of shear adhesion strength;

d) determination of tensile adhesion strength:

e) determination of transverse deformation:

f)determination of chemical resistance

2 Normative references

The following referenced documents are indispensable for the application of this part of SO 13007. For datedreferences, only the edition cited applies. For undated references, the latest edition of the referenceddocument (including any amendments) applies.

ISO 13006, Ceramic tiles 一 Definitions, classification, characteristics and marking

SO 13007-1, Ceramic tiles – Grouts and adhesives – Part 1: Terms, definitions and specifications foradhesives

General test conditions and procedures3

3.1 Sampling

A representative sample of at least 2 kg shall be used

3.2 Test conditions

Standard test conditions shall be (23 + 2) C and (50 : 5) % relative humidity and the speed of air in thetesting area less than 0,2 m/s. ther test conditions may be specified in Clause 4. The tolerance in the time otconditioning for all test specimens shall be as shown in Table 1.

3.3 Test materials

Condition all test materials, including water for at least 24 h under standard conditions. The adhesive undertest shall be within its shelf life, if this is specified.

3.3.1 Ceramic tiles

The tiles shall be checked prior to conditioning to ensure that they are unused, clean and dry. The type of tileshall be as specified under the specific test procedures given in Clause 4.

3.4 Mixing procedures

3.4.1Cementitious adhesives – C

The amount of water and liquid admix, or one or the other, required for preparing the adhesive shall be asstated by the manufacturer in mass fraction, .e. liquid to dry powder (in the case where a range of values isgiven, the average shall be used).

Using a minimum quantity of 2 kg of the powder and the recommended quantity of liquid, prepare theadhesive in a mixer of the planetary type using the slow speed settings (140 + 5) r/min and (62 : 5) r/minplanetary movement (see Fiqures 1 and 2).

Carry out the following procedure!

a) pour the liquid into the pan;

b) scatter the dry powder over the liquid;

mix for 30 s;c

d) take out the mixing paddle;

e) scrape down the paddle and pan within 1 min;

f) replace the paddle and mix for 1 min.

if reguired by the adhesive manufacturer’s instructions, let the adhesive mature as specified and then mix foran additional 15 s