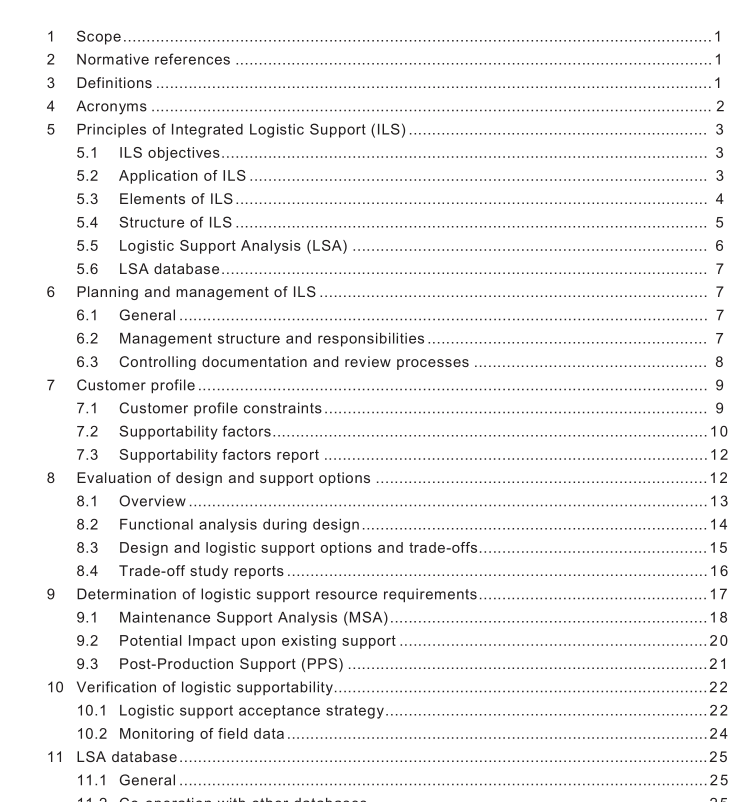

AS IEC 60300.3.12 pdf download

AS IEC 60300.3.12 pdf download Dependability management Part 3.12: Application guide—Integrated logistic support

1 Scope

This part of IEC 60300-3 is an application guide intended for use by a wide range of suppliers including large and small companies wishing to offer a competitive and quality product which is optimized for the purchaser and supplier for the complete product life cycle. This standard can be applied to both commercial and military products. It describes the process of ILS, and the various minimal common practices and logistic data analyses that should be undertaken to meet this objective.

2 Normative references

The following normative documents contain provisions which, through reference in this text, constitute provisions of this part of IEC 60300. For dated references, subsequent amend- ments to, or revisions of, any of these publications do not apply. However, parties to agreements based on this part of IEC 60300 are encouraged to investigate the possibility of applying the most recent editions of the normative documents indicated below. For undated references, the latest edition of the normative document referred to applies. Members of IEC and ISO maintain registers of currently valid International Standards.

IEC 60050-1 91 , International Electrotechnical Vocabulary (IEV) – Chapter 191: Dependability and quality of service

IEC 60300-3-3, Dependability management – Part 3: Application guide – Section 3: Life cycle costing

IEC 60300-3-1 1 , Dependability management – Part 3-11: Application guide – Reliability centred maintenance

IEC 60706-2, Guide on maintainability of equipment – Part 2 – Section 5: Maintainability studies during the design phase

IEC 6081 2, Analysis techniques for system reliability – Procedure for failure mode and effects analysis (FMEA)

IEC 61 1 60, Formal design review

3 Definitions

For the purposes of this part of IEC 60300 the definitions given in IEC 60050-1 91 apply,together with the following.

3.1

design life

period that the item is expected to meet its performance specification in an agreed environment and level of utilization with the recommended support

3.2

integrated logistic support (ILS)

management method by which all the logistic support services required by a customer can be brought together in a structured way and in harmony with a product

3.3

line replaceable unit (LRU)

lowest level of assembly, subassembly or component which is recommended to be exchanged during maintenance to effect a repair at a specified repair level

3.4

logistic support

all material and resources required for the operation and maintenance of a product including both hardware and software

3.5

logistic support analysis (LSA)

selective application of a range of tasks undertaken to assist in complying with supportability and other ILS objectives

3.6

provisioning

process of determining and acquiring the range and quantity of spares required to operate and maintain the product

3.7

supportability

degree to which product design characteristics and planned logistic support resources meet product operational utilization requirements