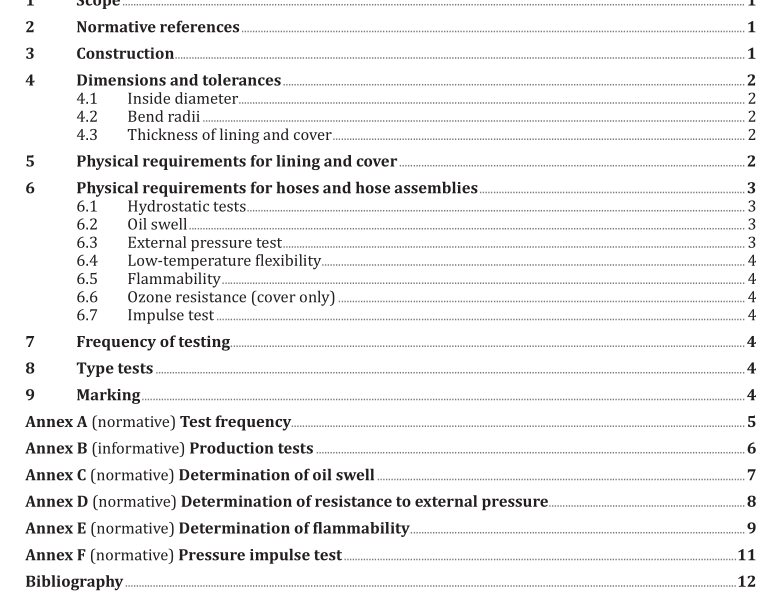

ISO 6806 pdf download

ISO 6806 pdf download Rubber hoses and hose assemblies for use in oil burners — Specification

This International Standard specifies the minimum requirements for rubber hoses and hose assembliesfor use in oil burners.

The following two types of hose assembly are specified

lype 1: Hose assemblies for flux and reflux, but not for insertion between the oil burner pump andthe atomizing connection; maximum working pressure 1,0 MPa(10 bar); maximum oil temperature100°C.

Type 2: Hose assemblies for insertion between the oil burner pump and the atomizing connection;working pressure 4,0 MPa (40 bar); maximum oil temperature 100 °C.

NOTEThe hose assemblies specified in this International Standard are not intended to be used, withoutspecial assessment, for purposes other than oil burner installations.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and areindispensable for its application. For dated references, only the edition cited applies. For undatedreferences, the latest edition of the referenced document (including any amendments) applies.

ISO 37, Rubber, vulcanized or thermoplastic – Determination oftensile stress-strain properties

ISO 48, Rubber. vulcanized or thermoplastic — Determination ofhardness (hardness between 10 IRHD and100 IRHD)

ISO 188,Rubber, vulcanized or thermoplastic — Accelerated ageing and heat resistance tests

ISO 1307, Rubber and plastics hoses — Hose sizes, minimum and maximum inside diameters, and toleranceson cut-to-length hoses

SO 1402, Rubber and plastics hoses and hose assemblies — Hydrostatic testing

ISO 1436, Rubber hoses and hose assemblies — Wire-braid-reinforced hydraulic types for oil-based or water’based fluids – Specification

ISO 1817, Rubber, vulcanized or thermoplastic — Determination ofthe effect of liquids

ISO 4671, Rubber and plastics hoses and hose assemblies – Methods of measurement of the dimensions ofhoses and the lengths ofhose assemblies

ISO 7326, Rubber and plastics hoses — Assessment ofozone resistance under static conditions

SO 10619-2:2011, Rubber and plastics hoses and tubing – Measurement of flexibility and stifness -Part 2: Bending tests at sub-ambient temperatures

3Construction

Hoses in accordance with this International Standard shall consist of either:aan internally smooth rubber lining and an external corrosion-resistant metal braid; or

b) an internally smooth rubber lining, a reinforcement consisting of one or more layers of textile or corrosion-resistant metal braid and a rubber outer cover.

The hoses shall be fitted with permanently attached couplings.

Both the couplings and the metal braid shall be provided with suitable corrosion protection. The metals used shall not have any deleterious effects on the rubber components.