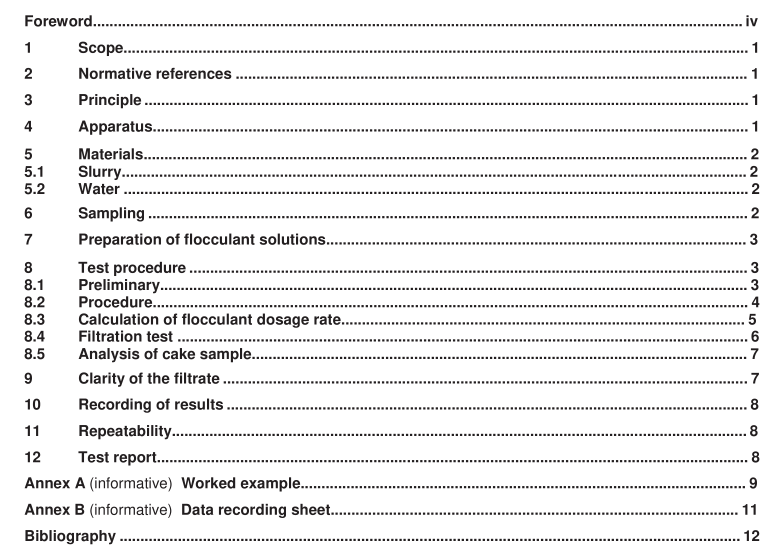

BS ISO 10086-2 pdf download

BS ISO 10086-2 pdf download Coal — Methods for evaluating flocculants for use in coal preparation — Part 2: Flocculants as filter aids in rotary vacuum filtration systems

1 Scope

This part of ISO 1 0086 specifies a method for the comparative evaluation of the performance of flocculants used as filter aids for rotary vacuum filtration applications on a given slurry.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 1 0086-1 :2000, Coal — Methods for evaluating flocculants for use in coal preparation — Part 1: Basic parameters

3 Principle

The performance of different flocculants on a given slurry is determined by measuring the cake yield and moisture content.

A flocculant solution is added to an aliquot of slurry in a beaker. A filter leaf is then applied to the flocculated sample and the cake thus produced on the apparatus is weighed wet, dried and reweighed. A measure of the efficiency of the flocculant is obtained from the cake yield and moisture content.

4 Apparatus

Ordinary laboratory apparatus and the following.

NOTE The apparatus is generally arranged as shown in Figure 1 .

4.1 Laboratory vacuum pump or piped vacuum system, capable of producing a vacuum better than that proposed for the plant equipment.

4.2 Vacuum gauge

4.3 Two-way valves, of at least 2 mm to 3 mm bore, manufactured in glass or plastics.

4.4 Buchner flask, with a minimum volume of 1 L.

4.5 Filter-leaf apparatus, consisting of a drainage plate and filter cloth in an assembly, as shown in Figure 4.

4.6 Vacuum tubing and glass/plastics tubing

4.7 Stirrers, motorized variable-speed stirrers, capable of speeds up to 1 000 r/min, one for flocculant preparation and one for sample homogenization.

4.8 Syringes, having capacities of 1 ml, 2 ml, 5 ml, 1 0 ml and 50 ml.

5 Materials

5.1 Slurry

The slurry for evaluation shall be collected and divided by the method described in ISO 1 0086-1 . The contents of each test cylinder shall then be poured into an 800 ml beaker for evaluation.

5.2 Water

The water used for the preparation of flocculant solutions shall be collected by the method described in ISO 1 0086-1 .

6 Sampling

The flocculant samples should be collected according to the recommendations described in ISO 1 0086-1 .

7 Preparation of flocculant solutions

The flocculant, both powder and liquid grades, shall be prepared in accordance with the methods specified in ISO 1 0086-1 .

8 Test procedure

8.1 Preliminary

The test procedure shall simulate the operating conditions of a rotary vacuum filter on a plant (see Figures 2 and 3). Where the slurry is taken from a plant using such equipment, the immersion and drying times in the test procedure shall be the same as on the plant equipment. Where these times are not known, or where no vacuum filtration system exists, the following times shall apply:

immersion time: 1 min 1 0 s;

drying time: 2 min.