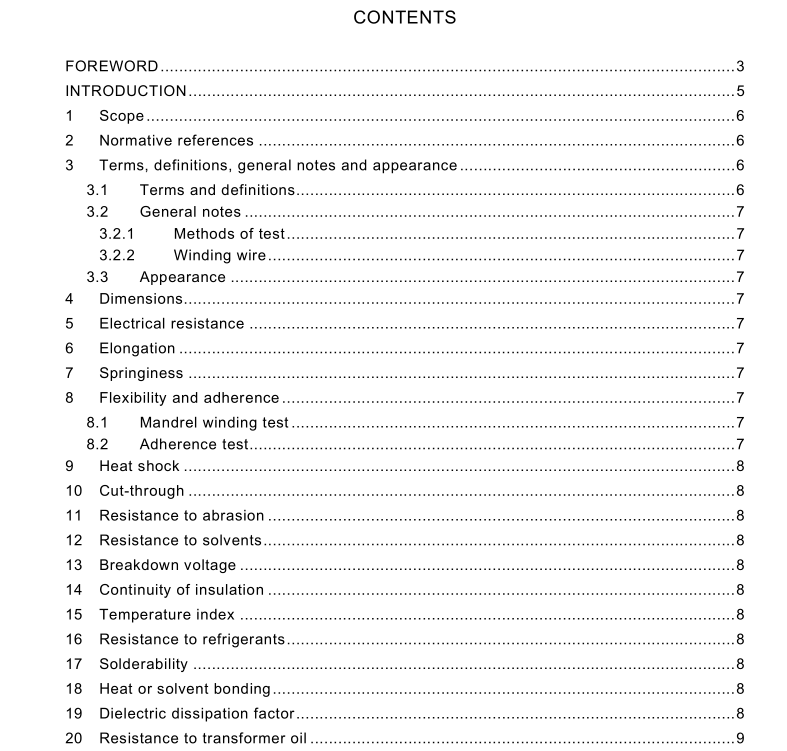

IEC 60317-17 pdf download

IEC 60317-17 pdf download Specifications for particular types of winding wires – Part 17: Polyvinyl acetal enamelled rectangular copper wire, class 105

1 Scope

This part of IEC 6031 7 specifies the requirements of enamelled rectangular copper winding wires of class 1 05 with a sole coating based on polyvinyl acetal resin, which can be modified provided it retains the chemical identity of the original resin and meets all specified wire requirements.

NOTE 1 A modified resin is a resin that has undergone a chemical change, or contains one or more additives to enhance certain performance or application characteristics.

NOTE 2 Polyvinyl acetate is a general name for a family of thermoplastic vinyl resins produced by the condensation of polyvinyl alcohol with an aldehyde. Examples are polyvinyl acetal, polyvinyl formal and polyvinyl butyral.

The range of nominal conductor dimensions covered by this document is:

– width: min. 2,0 mm max. 31 ,5 mm;

– thickness: min. 0,80 mm max. 1 0,00 mm.

Wires of grade 1 and grade 2 are included in this specification and apply to the complete range of conductors.

The specified combinations of width and thickness as well as the specified ratio of width/thickness are given in IEC 6031 7-0-2.

2 Normative references、

The following documents are referred to in the text in such a way that some or all of their content constitutes requirements of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

IEC 6031 7-0-2:2020, Specifications for particular types of winding wires – Part 0-2: General requirements – Enamelled rectangular copper wire

3 Terms, definitions, general notes and appearance

3.1 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 6031 7-0-2 apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.2 General notes

3.2.1 Methods of test Subclause

3.2 of IEC 6031 7-0-2:2020 applies. In case of inconsistencies between IEC 6031 7‑0-2 and this document, IEC 6031 7-1 7 shall prevail.

3.2.2 Winding wire Class 1 05 is a thermal class that requires a minimum temperature index of 1 05 and a heat shock temperature of at least 1 55 °C. The temperature in degrees Celsius corresponding to the temperature index is not necessarily that at which it is recommended that the wire be operated and this will depend on many factors, including the type of equipment involved.

3.3 Appearance

Subclause 3.3 of IEC 6031 7-0-2:2020 applies.

4 Dimensions

Clause 4 of IEC 6031 7-0-2:2020 applies.

5 Electrical resistance

Clause 5 of IEC 6031 7-0-2:2020 applies.

6 Elongation

Clause 6 of IEC 6031 7-0-2:2020 applies.

7 Springiness

Clause 7 of IEC 6031 7-0-2:2020 applies.

8 Flexibility and adherence

8.1 Mandrel winding test

The coating shall show no crack after the wire has been bent flatwise and edgewise on a mandrel with a diameter as specified in Table 1 .