ASME A16.18 pdf download

ASME A16.18 pdf download CAST COPPER ALLOY SOLDER JOINT PRESSURE FITTINGS

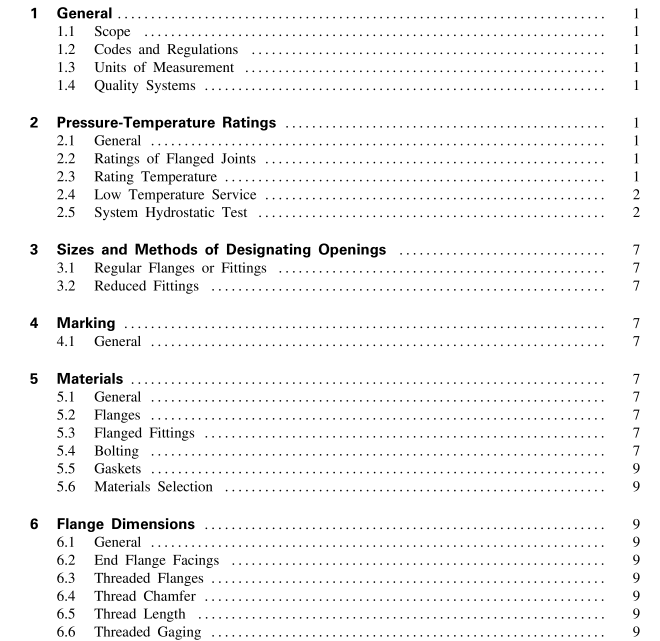

4 SIZE The size of the fittings shown in Table 3 and Table A1 corresponds to standard water tube size as shown in ASTM B 88, Specification for Seamless Copper Water Tube. The size of the threaded ends corresponds to nominal pipe size as shown in ASME B1.20.1. Fittings are designated by the size of the openings in the sequence illustrated in Fig. 1.

5 MARKING Each fitting shall be permanently marked with the manufacturer’s name or trademark and other applicable markings as required by MSS-SP-25. Marking of fittings less than Standard Water Tube Size 1 ⁄ 2 , or on any fitting where it damages soldering surfaces is not required.

6 MATERIAL Castings shall be copper alloy produced to meet:

(a) the requirement of ASTM B 62 Alloy C83600;

(b) the chemical and tensile requirements of ASTM B 584 Alloy C83800 or C84400 and in all other respects comply with the requirements of ASTM B 62.

7 METAL THICKNESS Dimensional variations occur in the casting process. Pattern equipment shall be designed to produce the metal thickness given for fittings in Table 3 or Table B3. The minimum wall-thickness shall not be less than 90% of the body and joint wall-thickness as shown in Table 3 or Table B3.

8 INSPECTION TOLERANCE8.1 Linear Dimensions

An inspection tolerance as shown in Table 2 shallbe allowed on center-to-shoulder,center-to-center,cen-ter-to-threaded end, and shoulder-to-threaded end di-mensions on all fittings having female solder (soldercup) ends,and on center-to-solder end and solder-to-threaded end dimensions on all fittings having malesolder (fitting) ends.

Coupling inspection limits for shoulder-to-shoulderand shoulder-to-end dimensions shall be double thoseshown in Table 2, except that the minus toleranceapplied to dimensions M,N, and w, and Tables 7 andB7 shall not result in a dimension less than 0.06 in.( 1.5 mm) for sizes ‘4 through 1 in.,inclusive,or adimension less than 0.09 in. (2.3 mm) for the largersizes.

The largest opening in the fitting governs the toleranceto be applied to all openings.

Tables 3 through 19 offer dimensions for pressurefittings covered by this standard.

8.2 Ovality

Maximum ovality shall not exceed 1 % of the maxi-mum diameters shown in Table 3 or Table B3. Theaverage of the maximum and minimum diameters mustbe within the dimensions shown in the table.

8.3 Gaging of Solder Joint Ends

8.3.1Standard Gaging Method. The standardmethod of gaging the diameter tolerances for male andfemale ends shall be by the use of plain plug and ringgages designed to hold the product within the limitsestablished in Table 3 or B3.

8.3.2 Optional Gaging Method. For gaging thediameter tolerance of male and female ends, the manu-facturer may use direct reading instruments instead ofring and plug gages as specified in para.8.3.1. Whengaging the diameters of male and female ends usingdirect reading instruments,refer to para.8.2.

8.4 Standard Gaging Method of Threaded Ends

The standard method of gaging the external andinternal threaded ends shall be in accordance with therequirements of ASME B1.20.1.