IEC 61086-1 pdf download

IEC 61086-1 pdf download Coatings for loaded printed wire boards (conformal coatings) – Part 1: Definitions, classification and general requirements

This part of lEC 61086 gives the definitions,classification and general requirements forelectrical insulating materials suitable for application as coatings for loaded printed wireboards (conformal coatings).

This standard excludes requirements for compatibility between such coatings and printed wireboards, this characteristic being evaluated in individual applications.

Surface modifiers are not classified as conformal coatings. They only provide a thin film thatdoes not cure and has low mar resistance.They are excluded from this standard.

Materials which conform to this standard meet established levels of performance.However,the selection of a material by a user for a specific application should be based on the actualrequirements necessary for adequate performance in that application and not based on thisstandard alone.

Terms and definitions

For the purposes of this document, the following terms and definitions apply.

2.1

conformal coating

electrical insulating material applied as a coating to loaded printed wire boards to produce athin layer conforming to the surface in order to provide a protective barrier against deleteriouseffects from environmental conditions

2.2

surface modifier

non-curing hydrophobic material, applied as a surface layer of thickness 1 um to 2 um to aloaded printed wiring board to protect against deleterious effects from environmentalconditions by changing the surface characteristics

2.3

oligomeric

oligomeric blended material derived from a low molecular mass acrylic material and other lowmolecular mass reactive materials (for example,polyester,epoxy,etc.), possibly with otheradditions to give specific properties

3classification

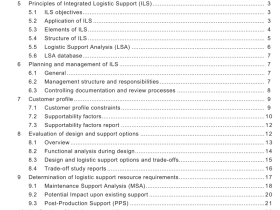

The types of conformal coatings covered by this standard shall be identified according to acode consisting of:

Number: indicating the classification of the material;

Letter:indicating the resin type, and

Suffix number distinguishing between the variants of each of the resin types.

Le premier chiffre du code doit indiquer la classification du matériau:

• Classe 1 Usage général

• Classe 2 Hautes performances

• Classe 3 Applications aérospatiales

Le Tableau 1 donne les lettres de code applicables aux différents types de résine et aux méthodes d’application.

The first number of the code shall indicate the classification of the material:

• Class 1 General purpose

• Class 2 High reliability

• Class 3 Aerospace applications

The code letters for the different resin types and the methods of application are indicated in the Table 1 .

The suffix number is inserted after the code letters for each resin type and is interpreted as follows:

• Suffix 1 : indicates that the conformal coating is water based.

• Suffix 2: indicates that the conformal coating is capable of being removed from the printed wire board by means of an appropriate solvent.

NOTE Suffixes 3, 4, 5, etc. may be introduced later to cover other variants of each resin type.